Abstract

Understanding complex cell–cell interactions and physiological microenvironments is critical for the development of new therapies for treating human diseases. Current animal models fail to accurately predict success of therapeutic compounds and clinical treatments. Advances in biomaterials, engineering, and additive manufacturing have led to the development of printed tissues, lab-on-chip devices, and, more recently, organ-on-chip systems. These technologies have promising applications for the fabrication of more physiologically representative human tissues and can be used for high-throughput testing of human cells and organoids. These organ-on-chip systems can be fabricated with integrated fluidics to allow for the precise control and manipulation of cellular microenvironments with multiple cell types. Further control over these cellular environments can be achieved with bioprinting, allowing for three-dimensional (3D) printing of multiple materials and cell types to provide precisely controlled structures manufactured in a one-step process. As cell behavior is highly dependent on the physical and chemical properties of the environment, the behavior of cells in two-dimensional and 3D culture systems varies drastically. Providing devices that can support long-term cell culture and controlled stimulation of 3D culture systems will have a profound impact on the study of physiological processes and disease, as well as the development of new therapies. This review highlights recent advances in organ-on-chip systems and 3D bioprinting techniques for the development of in vitro physiological models.

Export citation and abstract BibTeX RIS

Introduction

Organ-on-chip systems are versatile tools that can be used to recreate complex tissues in vitro to study human physiology and guide drug development. The key to creating representative ex vivo models is to incorporate relevant cell populations that mimic physiological structures in emulated tissue microenvironments [1]. Commonly used fabrication techniques (such as lithography and gel confinement) for the development of organ-on-chip systems have a limited capacity to create tissue structures with complex three-dimensional (3D) organization [1, 2]. To develop platforms housing organized cell and tissue constructs, 3D bioprinting offers the ability to construct tissues layer-by-layer using tailored scaffold materials with high-precision cell deposition [2]. The synergistic application of 3D bioprinting to construct tissues in organ-on-chip bioreactors has the potential to revolutionize in vitro organoid models through the inclusion of complex physiological structures in controlled extracellular environments.

In this review, the current progress of organ-on-chip systems utilizing fluidic and/or 3D bioprinting technologies is discussed. Each section will discuss the relevant physiological structures and interfaces that are necessary to mimic specific organ function and disease behavior outside of the body and describe the fluidic and bioprinting methods used to achieve effective emulation. Devices that incorporate both 3D bioprinting and fluidics will be highlighted and potential for further integration of the techniques will be summarized.

Biological fluidic systems

Fluidic devices, particularly microfluidics systems, have an extensive history of being used to miniaturize technology to reduce costs and manage smaller samples. Their use began with the genomics boom of the 1980s, continued with the biodefense programs of the 1990s, and are at the forefront of medicine today [3]. Microfluidics is the field of study regarding systems that handle small volumes (10−9 to 10−18 l) of fluid through channel dimensions on the order of one to hundreds of microns [3]. The primary benefit of these systems is the ability to finely manipulate and characterize small volumes of fluids; these devices maximize control over the microenvironment and minimize the use (and waste) of costly reagents or small biological samples. This technology has revolutionized the biomedical field as it facilitates the inexpensive production and use of devices used to study micro-scale interactions, particularly those of biological samples. Successful applications of microfluidics have made a large impact across science and medicine. For example, the integration of microfluidic technology with polymerase chain reaction (PCR) has facilitated faster, cheaper, and more precise analysis of nucleic acids [4]. Other systems have been developed to easily observe minute quantities of fluids to better understand and characterize chemical and biological reactions [5]. Microfluidic devices also have translational potential as demonstrated by the development of inexpensive point-of-care diagnostic devices [6] with the ability to identify infectious diseases, such as HIV/AIDS [7] and Lyme disease [8], as well as medical conditions, such as male infertility [9]. These technological advances have influenced the generation of many in vitro biological models through their minimal reagent consumption to achieve scalable results.

Organ-on-chip platforms are fluidic devices containing organized biological structures that emulate the physiological function, behavior, and response of their analogous organs in the human body [10, 11]. While there is extensive diversity amongst organ-on-chip platforms, each of them shares the same goal: to recreate the structure and physiological behavior of human organs outside of the body. These systems have been developed in university labs, national labs, federally funded research centers, and biotechnology companies across the world and hold great promise to improve the understanding of physiological systems, as well as facilitate the development of the next generation of medical treatments [12, 13]. Organ-on-chip systems have been used to study both normal physiological behavior [13, 14] and disease mechanisms [15, 16] in vitro over extended periods of time ranging from weeks to months. The introduction of organ-on-chip platforms in the drug development pipeline can significantly reduce the cost associated with animal testing and prevent ineffective and/or toxic compounds from proceeding into clinical trials [17]. Additional applications include high-throughput drug screening and personalized medical practices for diagnosis and treatment optimization [18].

3D Bioprinting

3D bioprinting is an advanced fabrication technology that is used for creating tissues of one or more cell types that can mimic the 3D geometry and structure of native tissue [19, 20]. While biomedical research has historically used two-dimensional (2D) cell culture for many models, 3D culture methods are gaining popularity as they have been shown to produce more relevant physiological responses in many situations; this topic has been covered in depth in another review article [21]. Bioprinting is a relatively new field, with the early '3D bioprinting' journal articles being published in 2006 [22–24]. Although the field of 3D bioprinting is young, the potential to print human organs stems from the invention of stereolithography by Charles Hull in 1983 [25, 26]. The invention of stereolithography gave rise to the field of additive manufacturing and led to the manufacturing of the 3D printer in 1986 [25]. Additive manufacturing was originally used with materials such as resin and acrylics. The use of additive manufacturing in machine shops and other fields eventually inspired medical researchers to consider the use of 3D printers to construct human organs [25]. Almost 15 years later, in 1999, Atala et al created a human bladder scaffold by 3D printing a polyglycolide (PGA) scaffold [27]. Bladder biopsies and muscle cells were harvested and expanded. Within five weeks of isolation, urothelial and muscle cells were seeded onto the printed bladder. Their group's work recreating a hollow organ represents a new frontier in tissue engineering and was widely recognized for its innovative application of existing technologies [27]. The strategy of 3D printing a scaffold and then seeding cells onto it led the way for a new field, called 3D bioprinting. Bioprinting differs from 3D printing in that it prints cell-laden bioinks, versus 3D printing, in which the inks do not contain cells [19].

The strength of 3D bioprinting lies in the ability to precisely control the placement of printed cells and biomaterials [27]. Applications of 3D bioprinting can be divided into several categories: organ fabrication for the purpose of performing an in vivo function (such as blood filtration), tissue fabrication for use as in vitro models for pharmaceutical drug testing, and physiological research [28]. 3D bioprinting of tissues for implantation and drug development can offer many advantages, including decreased costs, automation, and reproducibility [28]. In addition, 3D bioprinting can address one of the limiting factors of other tissue engineering strategies, size [29]. Large tissues are difficult to make with other in vitro techniques due to mass transfer limitations [29]. Introduction of vascularization can overcome these constraints and allow for the creation of larger tissues. 3D bioprinting can drastically improve vascularization in tissue engineering, a challenge which has yet to be surmounted by other techniques [30]. Addressing this limitation will be a large step in the clinical translation of bioprinting-generated tissue and organ constructs [30].

Vasculature

Vasculature is the highway for nutrients and waste in the body. Humans and other vertebrates have two kinds of vasculature that share a developmental origin but offer different functions. Blood vessels in the circulatory system export oxygen and small nutrients to the body and return chemical wastes, and lymph vessels drain interstitial fluid to the circulatory system while providing a battleground for the immune system. Both provide systemic molecular transport, which is key for drug transport and maintaining homeostasis. Vasculature-on-chip provides a platform for cross-talk between multiple cell and tissue types to replicate pathological function and physiological conditions [31, 32]. Consequently, vasculature is considered a minimal requirement for any engineered tissue [33, 34]. Vasculature-promoting cells such as human umbilical vein endothelial cells (HUVECs), embryonic stem cells (ESCs) and induced pluripotent stem cells (iPSCs) are included in bioinks, or in matrices that act in conjunction with bioinks, to produce these vasculature-on-chips and supplement other organ-on-chip systems [35]. Recent reviews have discussed in detail the body of work in bioprinted vasculature-on-chip systems [30, 36, 37]. Here, we highlight work in vasculature that has implemented microfluidics or bioprinting and the integration of the two for biomimetics in angiogenesis, vascular disease, lymphatic tissue, and implementation in other organ-on-chip systems.

Vasculature-on-chip technology was first used for by observing and understanding healthy vessel physiology, including thrombosis and angiogenesis, in microfluidic systems [38, 39]. Better understanding of healthy physiology allows for improved comparison to diseased states, such as the pathophysiology of congenital diseases, cancer, and cardiovascular diseases [38]. A leading cause of cardiovascular disease is atherogenesis. In a recent study, mechanical application of shear stress through a pneumatic air-ballooned membrane coupled with a chemical stimulus, exposure to tumor necrosis factor-alpha (TNF-α), caused leukocyte adhesion, a key first step in developing vessel-clogging plaque. Increasing the vessel model's restriction from 50% to 80% caused overexpression of intercellular adhesion molecule-1 (ICAM-1) [40]. Mechanical manipulation aided the group in creating the tunable 3D vessel model for noncommunicable disease. Another example of such a device replicated hereditary hemorrhagic telangiectasia (HHT), a cardiovascular syndrome that manifests in arteriovenous malformations (AVMs) without capillaries which are subject to frequent bursting [39]. By inhibiting growth factors the growing vasculature disorganized, causing shrunken vessels, typical of malformations of HHT. This demonstrated the physiology of the disease by modifying the cellular signals local to the tissue, which disrupted angiogenesis. Further, the monitoring of angiogenic factor release and heterogenous vascularization, or angiogenic invasion of a tissue, in tumor models has been made possible by developments in implementing vasculature to tumors-on-chips [41]. Several of these are discussed in a later section of this paper. The purpose of emulating vascularization in these systems is to show the growth of full blood vessels in a cancerous tissue. This contrasts with endothelialized organs-on-chips, in which a layer of endothelium is seeded on an existing tube.

Endothelialized structures aid in analyzing the interactions between flow, blood cells, and the vessels themselves. Tsvirkun et al analyzed in detail the presence of a glycocalyx layer covering the endothelium of a blood-vessel-on-a-chip under physiological flow, allowing a fluid shear stress of 0.2 Pa [42]. The surface layer from the seeded HUVECs was around 600 nm, which reflected conditions in vivo, whereas 2D cell culture developed a layer of around 10 nm. The development of an extracellular matrix (ECM) relevant to the physiological structure in vivo allowed for tunable blood flow analysis, of which the group called for further investigation. In recent years, an article was published containing simple, easy-to-follow instructions to construct endothelialized 3D in vitro vessel models with customizable features including stenosis (vessel narrowing), aneurysms (vessel ballooning), and bifurcation (split vessel) [43]. The materials for these do-it-yourself (DIY) vessels-on-chips are common and relatively inexpensive, although the technology is not ready for mass production [44].

More recently, another step towards physiological accuracy in vasculature-on-chip systems was taken when Shöneberg et al bioprinted a multi-layer blood vessel with 83% smooth muscle cell (SMC) viability, showing no statistical difference from cells pipetted onto the same hydrogels. While others have reported seeding cells in microfluidic chips to fabricate multilayered vessels, this group utilized a custom bioprinter [45, 46]. The bioprinter was custom-built with three printheads, with one containing HUVECs, a second containing SMCs, and a third containing thrombin for crosslinking. The outer, middle, and inner layer, composed of fibroblasts with ECM, SMCs, and HUVECs, respectively, resembled those found in vivo, creating a vessel about 1 mm in diameter with walls of 0.43 mm thickness. The inner layer of HUVECs expressed cadherin and cluster of differentiation 31 (CD31) molecules, which are essential for intercellular communication and tissue formation. Adding multiple layers of tissue greatly improves biomimicry of the controllable fluidic systems [46]. This system did not rely completely on 3D bioprinting, however, as the outermost layer of fibroblasts was cast onto the muscle cell layer. Improvements can still be made on the current technology to completely 3D-print vasculature from cultured cells.

A central limitation of in vitro tissue engineering strategies is the lack of an adequate blood vessel supply [47]. In vivo, a network of blood vessels supplies tissues with nutrients and oxygen [47]. Organ-on-chip platforms are restricted in size and complexity without vasculature-on-chip since diffusivity of nanoscale molecules through the ECM drops as though in a viscous fluid (1.34 times viscosity of water) [48]. During embryonic development, animals overcome the limitations of diffusive gas and small-molecule transfer by developing vascular networks [49]. Similarly, transferring nutrients and waste from small (1–2 nm) molecules to large proteins (10 nm) requires bulk transfer of fluids throughout an organ-on-chip. Dense vasculature systems are required to sustain thick (>3 mm) organ-on-chip systems for longer periods of time [50]. Large-scale fluidic systems only remain viable if a robust vascular network continues to survive engineered tissues [51]. The 3D bioprinted vasculature-on-chips have thus far produced mostly thin, short-lived vascularized systems. Recently, Kolesky et al developed a method to create a thick (>1 cm) and long-lasting (>6 weeks) bioprinted vascular system using a sacrificial bioink, composed of Pluronic and thrombin (figure 1) [52]. This fugitive bioink was printed in a crosshatched pattern to a thickness of 1 cm. Next, a surrounding matrix, containing HUVECs, hMSCs, and human neonatal dermal fibroblasts (HNDF), was 3D bioprinted around the crosshatched structure. Removal of the fugitive ink resulted in the formation of a connected network of vessels that supported endothelialization and retained cell viability up to 95%. After creating this structure, Kolesky et al found that adding osteogenic media to hMSC-printed tissue formed symmetric, bone-like tissue after 30 days. Previously, agarose also proved to be a viable sacrificial ink that could provide vessels in a matrix without the reported cytotoxicity associated with Pluronic [53].

Figure 1. Bioprinting vasculature for organ-on-chip applications. (A) Illustrated fabrication protocol for the production of hollow channels in a hydrogel. (i) An extrusion-based bioprinter prints agarose fibers. (ii) A hydrogel precursor is poured over the 3D bioprinted agarose and photocrosslinked. (iii) Agarose fibers are removed. (iv) Fully perfusable microchannels are formed. Reproduced from [53] with permission from The Royal Society of Chemistry. (B) Schematic of the vasculature-on-chip tissue fabrication process. (i) Fugitive Pluronic and thrombin and gelatin-fibrinogen cell-laden inks are printed into the fluidic chamber. (ii) Gelatin-fibrinogen-thrombin ECM hydrogel is cast over the printed inks. Thrombin induces rapid polymerization of molten ECM into a gel. Transgluatminase slowly cross-links the gelatin and fibrin. (iii) Upon cooling, the fugitive ink liquefies and is evacuated, leaving behind a vascular network, which is (iv) endothelialized and perfused via an external pump. Reproduced from [52] with permission from PNAS.

Download figure:

Standard image High-resolution imageWhile progress is steady in 3D bioprinting circulatory vasculature for 3D organ-on-chip systems, little work has been done to advance 3D bioprinting in the closely-related lymphatic vasculature [19, 54]. Casting and cell-seeding have been implemented in the past to fabricate human lymph-nodes-on-chips to acquire real-time data for immune system response and antigen uptake after treating tumor tissue with anti-cancer drugs [55]. These microfluidic chips have been applied to study the effects of the anti-cancer drugs rhomidespin and IFN-α2b on dendritic cell antigen-uptake and subsequent phagocytosis of apoptotic tumor cells. The research took a closer look at the human immune response post-cancer treatment in real-time, establishing a human cell-based alternative to in vivo animal testing. As the lymphatic system plays an important role in immune response, wound healing, and metastasis, future research could be guided towards promoting the lymphatic system to the list of 3D bioprinted organ systems already established [19].

Developments in 3D bioprinting offer improvements in the structure and function of vasculature-on-chip models. Bioprinting improves upon existing casting and seeding methods, resulting in increased resolution, customizability, and automation [19, 44]. Bioprinters increase the accuracy of cell placement by creating physiological structures based on templates of native patient vasculature captured via magnetic resonance imaging (MRI). The 3D-printed vasculature-on-chip systems can then be mechanically manipulated to elicit physiological response [56]. Mechanical strength of 3D bioprinted vessels-on chips is greater than cell-seeded structures, as shown in work by Gao et al [57]. The authors suggested that the 3D bioprinted vessel could be implemented for training in surgery and in studying vessel physiology in vitro. Cui et al demonstrated that a 3D-printed vascular network control improved osteogenesis and regeneration relative to static culture [58]. As vasculature is vital for tissue growth, these findings encourage integration of 3D bioprinted vessels with organs-on-chips. Progress in organ-on-chip and bioprinted models of vasculature is summarized in table 1.

Table 1. Summary of progress related to vasculature.

| Reference | Description | Major Advance |

|---|---|---|

| Vasculature-on-chip (without bioprinting) | ||

| van der Meer et al [39] | Created a model for hereditary hemorrhagic telangiectasia (HHT) to relate growth factor inhibition to physiology | Demonstrated drug effects on vascularization in a microfluidic vessel |

| Tsvirkun et al [42] | Simulated blood flow through an endothelialized fluidic vessel | Observed endothelial surface layer in cell-seeded vessel-on-chip |

| Mannino et al [43] | Created endothelialized models of stenosis, bifurcation, aneurysm | Established a simple protocol for creating variations of vasculature-on-a-chip |

| Hasan et al [59] | Made a multilayered microfluidic vessel in photocrosslinkable hydrogel | Demonstrated permeability and tunability of thickness in a multilayer vessel |

| Zheng et al [38] | Used lithography to form endothelialized microfluidic vessels within a collagen matrix | Elucidated the angiogenic activities of the endothelia |

| Venugopal et al [40] | Monocytes were perfused over inflamed human umbilical endothelial cell monolayer at different channel constrictions | Facilitated study of hemodynamics and leukocyte-endothelial interactions |

| Sakaguchi et al [51] | Triple-layer cardiac cell sheets co-incubated with endothelial cells that migrate | Vascularized tissue constructs that overcame tissue thickness limitations |

| Vasculature-on-chip (with bioprinting) | ||

| Schöneberg et al [46] | Used drop-on-demand bioprinting to print human umbilical vein endothelial cells (HUVECs) and dermal fibroblasts in fibrin and collagen in native blood vessel configurations, which were then cultivated in fluidic bioreactors | Achieved perfusable vessel models with a biofunctional multilayer wall composition |

| Lee et al [50] | Printed HUVECs in a collagen scaffold perfused with physiological shear | Model for investigating mechanisms vascular remodeling under flow conditions |

| Kolesky et al [52] | HUVECs, neonatal dermal fibroblasts, and bone-marrow derived mesenchymal stem cells printed a gelatin fibrinogen ink | Vascularized, thick (>1 cm) tissues that can be perfused on a chip |

| Bertassoni et al [53] | Micromolding strategy using bioprinted template fibers fabricated microchannel networks in multiple hydrogel materials | Effective technique for vascularization of hydrogel constructs |

| Gao et al [60] | 3D vascular structures (fibroblasts, smooth muscle, and endothelial cells) with multi-level fluidic channels fabricated by extrusion-based bioprinting | Structural similarity, sufficient mechanical strength and biocompatibility to be used a new strategy for printing functional vessels |

Skin

Skin is a large, intricate organ with many important physiological functions [61–63]. The skin serves as a barrier, protecting the body from pathogens, toxic chemicals, mechanical disturbances, and ultraviolet radiation [64]. In addition to its protective functions, the skin has passive functions, i.e. prevention of dehydration, maintenance of oxygen, nitrogen, and hydrogen gas concentrations, and thermoregulation [61, 62]. The skin's accessibility and large surface area have led to its consideration as a route for drug delivery [61]. Skin models are of interest for both risk assessment of pharmaceutical compounds in healthy tissue and for modeling diseased tissue states, i.e. fibrosis and tumor models [62]. The human skin's physiological functions and potential as a method for drug delivery have led to an urgent need to develop improved skin models [61].

Recently, skin-on-chip models have emerged, largely due to the ability of integrated fluidics to recapitulate the mechanical forces and biochemical gradients in the human skin's 3D microenvironment [61]. While skin-on-chip system models mimic the native microenvironment with higher fidelity, they are also lower in cost and able to be maintained for longer time than other pre-clinical models. In 2014, Abaci et al developed a microfluidic skin-on-chip system using human skin equivalents (HSE), which are engineered substitutes composed of primary human skin cells and ECM components [65, 66]. The platform was comprised of two polydimethylsiloxane (PDMS) layers, which were separated by a porous polycarbonate membrane. The upper PDMS layer contained a circular compartment to house the HSEs, while the lower layer had five parallel microchannels. The microchannels were constructed with dimensions determined by previously reported blood residence times in human skin tissues, recapitulating physiological molecular transport and allowing for this HSE-on-chip to be integrated with other organ-on-chips in the future. The design of this HSE-on-chip allowed for pump-free, long-term maintenance of HSEs. Additionally, this model established an air-epidermal interface, a critical component needed for the maturation and differentiation of HSEs. Another advantage of this platform is the 36-fold reduction in the quantity of both cells and media required for maintenance, compared to that needed for more traditional platforms, i.e. Transwell assays. One of the skin's primary functions is to serve as a mechanical, water, chemical, thermal, immunological and microorganism barrier [67]. This platform was validated to maintain skin barrier function for three weeks, via a transdermal transport model. The barrier function of these constructs was evaluated by adding a solution of oligonucleotides tagged with fluorescein amidite on the surface of the skin constructs. Media was collected and the concentration of dye was calculated. The measured concentration in the media showed that the permeability of oligonucleotides through the HSE was not significantly different in week 1, 2, or 3, validating that the barrier function was maintained for three weeks. In addition, this platform was used as a drug testing model for doxorubicin treatment, observing cell structure.

This HSE-on-chip showed promise as a more accurate and lower cost alternative to other in vitro platforms for the testing of drug candidates on skin tissue. Another skin-on-chip model from Wufuer et al co-cultured epidermal, dermal and endothelial cells (ECs) in three separate layers, each separated by a porous membrane to allow for interlayer communication [68]. Immortalized human keratinocytes (HaCaTs), fibroblasts, and HUVECs were cultured in the three layers, respectively, mimicking the epithelial and endothelial barriers. TNF-α was applied to the fibroblasts, or dermal layers, to induce both skin inflammation and edema. Expression levels of pro-inflammatory cytokines were measured to demonstrate the system's ability to recreate in vivo inflammatory response. In addition, the system was then treated with dexamethasone, a popular drug used for treating inflammation. Dexamethasone reduced the TNF-α induced inflammation and edema, validating the system's utility as a model for both the study of disease and for drug testing.

Traditional culture systems are limited by their weak recapitulation of the skin's barrier function [69]. One probable cause of this weakness is the lack of mechanical forces and dynamic flow in traditional culture systems. In 2017, Sriram et al combined a dermal matrix, composed of fibrin, with organ-on-chip technology, creating a full-thickness human skin-on-chip [69]. Their system was comprised of a fluidic bioreactor, with dermal matrix cast inside of the culture chamber, seeded with keratinocytes. The basal side of the dermal matrix was shielded from shear stresses by a support membrane. This design resulted in shear stresses acting only on the external layer of the epidermis and the cells inside. Interstitial flow enhanced the transport of nutrients and induced morphogenic effects in the fibroblasts and keratinocytes, resulting in greater differentiation and expression of key markers, along with increased barrier function, which was evaluated via Confocal Raman spectroscopy to analyze water and keratin content, two major contributors to the skin's barrier function. Mechanical forces applied to skin-on-chip systems not only include shear or fluid forces, but also mechanical forces, such as stretching [70]. A study by Lim et al created a human fibroblast and keratinocyte organ-on-chip model that was stretched uniaxially by 10% for 12 hours per day. This technique resulted in a wrinkled skin-on-chip (WSOC) model, and induced aging in skin-on-chip. The WSOC model exhibited decreased cell proliferation and production of collagen, fibronectin, and keratin and formed wrinkles as a result of not being able to withstand tensile stress, making it a model platform to test anti-wrinkle agents for cosmetic and medical applications.

Skin-on-chip models also offer utility as a platform to study irritation from agents that encounter the skin. Allergic contact dermatitis and irritant contact dermatitis are two common health problems, stemming from skin sensitization [71]. In addition to recapitulating the skin's physiological structure and drug response, another important component to include in a skin-on-chip model is immune competence. A model to test the allergic potential of all ingredients is of high value, as all components in a cosmetic or pharmacological product have the potential to induce a skin allergy or cause irritation. A miniaturized co-culture, with both immortalized human keratinocytes and monocytes, was combined with on-chip technology by Ramadan et al to create an immune competent skin-on-chip model. The immune cells in this model were reported to migrate and respond to skin sensitizers, modeling the interaction between keratinocytes and dendritic cells and demonstrating the potential use of this model as a tool for the study of skin sensitization and drug-induced toxicity.

3D bioprinted skin tissue is of high relevance as a technique for engineering skin constructs for wound healing [72]. Engineered skin substitutes are replacements used to aid in wound closure and improve aesthetics, especially in burn patients. Burn injuries are typically treated via autologous split-thickness skin grafts (ASSG) [72]. However, despite the success of ASSG over previous treatment methods, ASSG is limited in its capabilities. Since it is impossible to predict both the size, number, shape, and extent of a patient's burn, it is difficult to obtain donor tissue of the same parameters. Bioprinting of skin tissue may offer an alternative to ASSG, with more opportunities to personalize the tissue constructs. Bioprinting of skin tissue has been studied both in vitro and in situ, with many different cell and scaffold sources [73–83]. 3D bioprinted skin offers many advantages, such as improved personalization by incorporating patient-derived cells and enhanced plasticity and extensibility due to relevant cell organization and material patterning. However, despite its advantages, 3D bioprinting still has challenges that need to be overcome, such as availability to patients (i.e. transporting between site fabrication and clinical use site) and a lack of a vascular network for transport. Recent work by Albanna et al addresses the challenge of transporting bioprinted skin constructs to patients in clinical setting, demonstrating both design and proof-of-concept for a mobile bioprinting skin platform for on-site wound management [84]. Design criteria for the system included: (1) portability and capability to be transported quickly (2) ability to identify and measure wound size and topography accurately (3) capability to deliver multiple cell types with precise spatial orientation (4) can be easily sterilized and (5) is easily operated and has low-cost maintenance. Key components of this system include a hand-held 3D wound scanner and a printer-head with XYZ movement, mounted on a frame that is both small and mobile enough to be portable in an operating room. The developed bioprinting system combines wound scanning imaging technology with an inkjet-based bioprinter for a personalized wound treatment approach, precisely dispensing different cell types to the appropriate area. Proof-of-concept demonstrations were performed in both murine and porcine models, where the regenerated tissues had both the dermal structure and composition of healthy skin. While further studies will be needed to assess the long-term function of this bioprinted skin and expand this technology for full-thickness burns, this platform represents a breakthrough for personalized wound treatment and on-site bioprinting in a clinical setting.

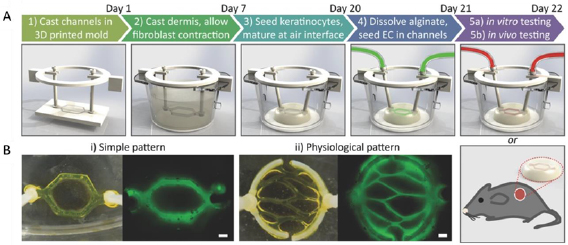

An additional challenge of skin tissue engineering for clinical applications is the vascularization of engineered tissue constructs. Vascularization is crucial for long-term survival and functionality of full-thickness skin constructs, in addition to being necessary for engraftment [85]. While there are engineered skin replacements currently used in clinical settings, a competent full thickness substitute requires the ability to be vascularized [86]. As a result, complete, full-thickness substitutes are less common. The combination of bioprinting with skin-on-chip platforms may offer advantages, combining the strengths of both techniques for both improved skin tissue models and replacements. However, to our knowledge, while there have been studies combining bioprinting with organ-on-chip for other organs and tissues, there has yet to be work combining these two for skin applications. Despite the lack of work in this field, there are studies combining 3D printing with fluid perfusion, demonstrating the potential benefits of this technology pairing, such as marrying the controlled geometry of micropatterned vasculature networks, offered by 3D printing, with the improved and more efficient exchange of nutrients and oxygen, offered by a perfusion-based system. In 2016, Abaci et al published a study incorporating 3D, perfusable vascular networks in HSEs (figure 2) [85]. They used 3D printing to mold vasculature patterns, inlet and outlets for perfusion, and holders to position the vasculature within the HSEs. These 3D printed molds were then used to make sacrificial microchannels that were embedded in a dermal compartment comprised of collagen gel and dermal fibroblasts. Keratinocytes were seeded on top of the dermal compartment and ECs were seeded inside of the channels. This study was unique in that its vasculature was both micropatterned and perfusable. These components allow for use as a platform to study systemic drug delivery. We believe that this type of work is a first step in moving towards the combination of bioprinting and organ-on-a-chip for skin tissue, which will offer both the spatial control over cellular placement as is seen with 3D bioprinting and the vascular perfusion of organ-on-chip. Progress of organ-on-chip and bioprinted models of skin is summarized in table 2.

Figure 2. Development of vascularized HSEs using bioprinting and microfluidics. (A) Animated procedure for the formation of vascularized skin tissue. Sacrificial alginate was printed in the desired vasculature pattern and encased in collagen seeded with fibroblasts. Keratinocytes were seeded on top of the skin construct and the tissue was incubated to mature. The alginate was dissolved, and the hollow lumen was seeded with endothelial cells to create the dermal vasculature. (B) Photographs and fluorescent images (using fluorescently tagged alginate) of two vasculature patterns. Scale bar = 600 µm. Reproduced from [85] with permission from John Wiley & Sons. © 2016 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.

Download figure:

Standard image High-resolution imageTable 2. Summary of progress related to skin.

| Reference | Description | Major advance |

|---|---|---|

| Skin-on-chip (without bioprinting) | ||

| Abaci et al [65] | Established air-epidermal interface with a microfluidic platform for culture of human skin equivalents (HSEs) with epidermal and dermal compartments | Examined toxic effects of Doxorubicin on skin cells and structure to validate drug testing capacity |

| Wufuer et al [68] | Microfluidic device with 3 layers for co-culture of epithelial, dermal, and endothelial components | Application of tumor necrosis factor alpha (TNF-α) induced inflammation and edema, showing application for testing toxicity of cosmetics and drugs |

| Sriram et al [69] | Co-cultured human fibroblasts with neonatal immortalized keratinocytes (N/TERT) in a fibrin-based matrix combined with organ-on-a-chip | Improved epidermal morphogenesis and differentiation |

| Lim et al [70] | Fibroblast and keratinocytes perfused with media and uniaxially stretched 10% for 12 h d−1 for 7 d | Decreased production of collagen, fibronectin, and collagen suggests use as a model for skin aging |

| Ramadan et al [71] | Miniaturized immune model comprised of human keratinocytes co-cultured with a human leukemic monocyte lymphoma cell line (to model dendritic cells) | Investigation of the effect of ultraviolet (UV) and chemical treatment allowed for study of protective nature of keratinocyte layer |

| Bioprinted skin | ||

| Koch et al [73] | Laser-assisted bioprinting of fibroblasts and keratinocytes embedded in collagen | Formation of adhering and gap junctions, which are crucial for tissue morphogenesis and cohesion |

| Skardal et al [76] | Amniotic fluid-derived stem cells and bone marrow-derived mesenchymal stem cells resuspended in fibrin-collagen gel and printed over wound in mice | Increased microvessel density, capillary diameters and tracking of fluorescently labelled cells indicate that bioprinting amniotic fluid-derived stem (AFS) cells could be an effective treatment for full thickness burns and injury |

| Albanna et al [84] | Design and validation of a mobile skin bioprinting system coupled with integrated imaging technology for precise on-site delivery of fibroblasts and keratinocytes to an injury | Regenerated tissues show the dermal structure and composition of healthy skin, with collagen deposition |

| Abaci et al [85] | 3D printed HSEs with pluripotent stem cell-derived endothelial cells to form micropatterned vascular networks connected to the HSEs | Application to cutaneous wounds in immunodeficient mice demonstrates promotion of neovascularizaton during wound healing |

Bone

Bone is a metabolically active structure that supports the physical structure and integrity of the body. It maintains mineral homeostasis through bone turnover, the continuous process in which bone is formed and resorbed over a period of time. Osteocytes, osteoblasts, and osteoclasts are the main cellular components of bone tissue. Osteoblasts are located on bone surfaces and are responsible for mineralized matrix deposition. During the mineralized matrix deposition process, some of the osteoblasts are embedded in the matrix, becoming osteocytes and connecting to form networks. The counterparts of osteoblasts in bone are multinucleated cells called osteoclasts; these cells conduct the destructive part of bone turnover by resorbing mineralized bone. Bone health is an integral component to high quality of life, but the common and lethal nature of bone disease has led to the urgent need for the development of human-representative, predictive systems to aid in pre-clinical drug screening and patient treatment [15, 87]. The skeletal system is the most frequent target of metastasizing breast and prostate cancer; breast cancer patients with metastatic tumors in the bones have a five-year survival rate of only 20% [88, 89]. Osteoporosis, a 'silent' but serious disease, occurs when bone turnover is impaired and significantly increases the risk of bone fracture both in men and women over the age of 50. Several drug classes (including bisphosphonates and synthetic parathyroid hormones) were developed in the 2000s to slow bone breakdown or increase the production of new bone for osteoporosis treatment; each posed problems with long-term use, including elevated cancer risk, blood clots, and stroke [90]. The prevalence of this condition has made systems mimicking bone turnover and physiological drug response highly desirable. Emerging bone-on-chip technology has the potential to model human tissue in a more sophisticated model, improving the process of drug screening [87].

Achieving organs of relevant physiological function is no easy task [87]. The native bone consists of mineral matrix and proteins, with entrapped bone cells and vascular networks. The components of bone assemble hierarchically to provide stiffness and toughness, mechanical properties that relate to a material's resistance to deformation and ability to absorb energy without fracture [91]. Simulation of specific bone properties on a microfluidic device requires consideration of three main aspects. The first is the 3D organizational structure of bone matrix (mainly mineral and collagen), including the location of bone cells and vasculature. This aspect is fundamental for bone-on-chip technology due to the unique mechanical properties of the microenvironment [87]. The second consideration for recreating bone ex vivo is the spatially-defined patterns of soluble and matrix-embedded growth factors provided to cells. Growth factors exist in two forms, as solid and soluble molecules, and are immobilized within the ECM to cell surfaces [92]. In 2009, Phillippi et al used bone morphogenic protein (BMP) 2, combined with inkjet bioprinting, to pattern muscle-derived stem cells into spatially defined regions of osteogenic and myogenic cells. This study provided a proof-of-concept for using patterns of immobilized growth factors to spatially control differentiation of stem cells, with future implications for regenerative medicine. The final consideration for bone mimicry is the dynamic mechanical stimulations (e.g. fluid flow, strain, and hydrostatic pressure) exerted on bone cells. Bone's trabecular structure determines its load bearing capacity, and mechanical forces regulate bone cell fate, function, and bone turnover through the entire lifespan of tissue [56, 93].

Some researchers have focused on the development of bone-on-chip for cell co-culture to monitor cell–cell interactions and cancer metastasis. A microfluidic co-culture platform was developed to study osteocyte–osteoclast–osteoblast communication in the presence of mechanical stimulation [94]. Three different chambers connected by microchannels were designed to culture osteocytes, osteoclasts and osteoblasts, respectively. In this system, the osteoclasts were exposed to conditioned cell culture media from mechanically-stimulated osteocytes, and the osteoblasts were exposed to doubly conditioned media that contained soluble signals from both the osteocytes and stimulated osteoclasts. The effects of these soluble signals, from the conditioned culture media, on bone formation were quantified and compared to studies in which cells were directly stimulated mechanically. Another interesting research area is the use of microfluidic chips for the investigation of mechanotransduction in bone cells. Shear stress was applied to osteoblasts cultured on cell-matrix micro stamps, and the dynamic intracellular calcium response of a single cell was measured [95].

Bone cell activity and function are strongly dependent on the 3D microenvironment in which a large array of biochemical signals is present. Movilla et al used collagen-based hydrogels for 3D osteoblast culture in a microfluidic device and analyzed the impact of ECM properties and growth factor gradients on 3D osteoblast movement and matrix degradation [96]. Their results showed that the hydrogel mechanical properties, platelet derived growth factor β gradient, and ability of the cells to remodel the matrix affect the osteoblast's migration pattern. The 3D microfluidic approaches are also representative toolkits for modeling the dynamic microenvironment of cancer metastasis to bone. Marturano-Kruik et al developed a perfused bone perivascular niche-on-chip, using bone decellularized extracellular matrix (dECM), to support the cultivation of macroscopic bone tissues through precisely controlled flow. This device allowed live assessment of tissue development and vascularization over long periods of culture (over several weeks) and was used to elucidate the role of the bone perivascular niche in breast cancer metastatic colonization [97]. Further discussion of metastatic cancer models involving bone can be found in the 'Cancer' section below.

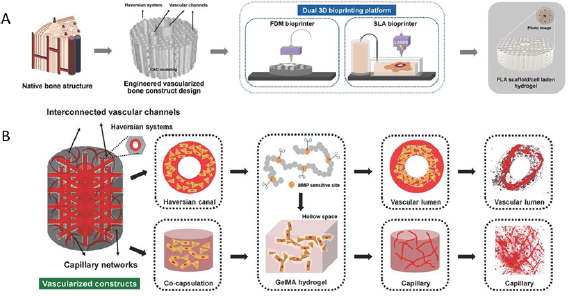

To make significant strides in bone-on-chip technology for drug screening, the next challenge is to establish more representative bone-mimicking micro-organoids integrated with vasculature to model a reductionist bone-on-chip [15]. Currently, 3D bioprinting technologies are mainly used to generate scaffolds replicating patient morphological features for repairing and regenerating bone defects [58]. The strategy of 3D bioprinting allows for the use of cell-laden bioinks to generate bone substitutes with in vivo-like bone tissue structures [58] and holds great potential to create models for drug screening [99]. In 2016, Cui et al used a dual bioprinting platform, comprised of fused deposition modeling and stereolithography based bioprinters, to alternately deposit polylactide fibers and gelatin methacrylate hydrogels, with encapsulated cells. Immobilized BMP2 and vascular endothelial growth factor resulted in a complex osteogenic bone construct with a vascular network, mimicking in vivo bone tissue. It is also possible to manufacture preformed vasculature in bioprinted scaffolds (figure 3) [58, 98, 100]. By exploiting the respective strengths of 3D bioprinting and microfluidics, it is possible to develop the next generation of bone-on-chip models with biomimetic reconstructions of bone tissue [98]. Despite the excellent potential of the technology, using 3D bioprinting to construct bone-on-chip systems still has several critical challenges. First, 3D bioprinted, cellularized constructs tend to have relatively low activity of embedded cells. Several approaches have been developed to increase bone cell activity, including agarose gels with incorporated bioceramic materials (polyphosphate-calcium complexes, bioglass) and nanoclay used as a bioink to increase bone cell proliferation [98, 101–103]. Second, the reconstruction of microscale scaffolds for bone-on-chip is restricted by low-resolution of bioprinting. Recent microfluidic-based strategies have facilitated the continuous fabrication of cell-laden microfibers with hierarchically organized osteon-like architecture [104, 105]. Cell-laden microfibers are mechanically rigid and provide cells with a predefined microenvironment. These fibers can define the architecture of tissue engineered constructs and can be used to recapitulate bone microstructures within microfluidic devices. Lastly, 3D bioprinting currently uses hydrogels with mechanical properties dissimilar from bone tissue. Bone tissue has peculiar characteristics as bone mineral confers high stiffness and mechanical resistance to bone tissue. Bone cell activity and function are heavily influenced by ECM stiffness [106]. Increases in the mechanical properties, such as viscosity and stiffness, of printable hydrogels must be considered. Despite the limitations discussed, the use of 3D bioprinting has great potential to close the gap between in vitro bone models and physiological bone tissues. The integration of 3D bioprinting with microfluidics is a promising technology for the construction of bone-on-chip systems. Progress in organ-on-chip and bioprinted models of bone is summarized in table 3.

Figure 3. Fabrication of vascularized bone constructs via dual 3D bioprinting. (A) Concurrent use of fused deposition modeling (FDM) and stereolithography (SLA) bioprinting methods to generate porous, cell-laden polylactic acid (PLA) scaffolds. (B) This technology was applied to generate scaffolds with interconnected large vasculature and capillaries formed from matrix metalloproteinase (MMP)- sensitive gelatin methacryloyl (GelMA). Reproduced from [58] with permission from John Wiley & Sons. © 2016 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.

Download figure:

Standard image High-resolution imageTable 3. Summary of progress related to bone.

| Reference | Description | Major Advance |

|---|---|---|

| Bone-on-chip (without bioprinting) | ||

| George et al [94] | Seeded a modular microfluidic system with osteocytes, osteoclasts, and osteoblasts to study intercell communication through soluble factors and response to mechanical loading | Generated microfluidic devices capable of transmitting mechanical force to cells |

| Jeon et al [95] | Used a PDMS device to provide shear stress to osteoblast-like bone cells seeded on fibronectin for single cell analysis | Platform facilitated the quantification of intracellular calcium transport |

| Movilla et al [96] | Recreated biochemical gradient of platelet derived growth factor BB across a collagen hydrogel seeded with osteoblasts | Determined that osteoblast migration is heavily dependent on the cell's ability to remodel the ECM |

| Marturano-Kruik et al [97] | Seeded bone marrow MSCs and endothelial cells into decellularized bone matrix in a microfluidic device | Showed self-assembly of vasculature and bone structures in dECM |

| Bioprinted bone | ||

| Phillippi et al [92] | Patterned BMP onto fibrin-coated glass with an inkjet printer to differentiate adult stem cells into osteogenic cells | Growth factors were patterned using inkjet bioprinting for tissue engineering |

| Cui et al [58] | Used both FDM and SLA bioprinting to construct spatially heterogeneous bone scaffolds for MSC and HUVEC co-culture | Simultaneous use of two bioprinting methods to control localization of bioactive factors |

| Neufurth et al [101] | Printed osteoblast-like cells in an alginate/gelatin hydrogel coated with an agarose solution | Demonstrated the addition of an enriched agarose to induce cell proliferation and bone mineralization in a bioinert gel |

| Wang et al [102] | Incorporated bioglass into an alginate/gelatin hydrogel with osteoblast-like cells to augment mineralization | Bioglass-laden hydrogels elevated cell proliferation and calcium phosphate and carbonate mineralization |

| Zuo et al [104] | Extruded HUVEC and osteoblast-like cells into a perfusable hollow fiber using a microfluidic coaxial printing method | Osteoblast-like cells and HUVECS demonstrated upregulated gene expression and proliferation due to their 3D conformation and localization |

| Wei et al [105] | Fabricated osteon-like microfibers using a microfluidic chip extruding HUVEC and osteoblast-like cells encapsulated in RGD-modified alginate | Printed 3D structure facilitated differentiation and expression of osteogenic and vasculogenic genes |

Brain

The brain is a complex, segmented organ that is responsible for controlling the functions of the body by neural activity in distinct regions [107]. Microfluidic models of the human brain aim to study a vast array of phenomena including microenvironmental conditions, physiological interfaces, electrophysiological properties, and disease states. Comprehensive reviews of these microfluidic devices are available from Yi et al [108] and Zhuang et al [109]. Many microfluidic devices have incorporated microelectrode arrays that are useful for studying electrical activity in brain slices and neuronal networks. These devices have also been used to study the progression of neurodegenerative diseases (such as Alzheimer's and Parkinson's Disease) and the injury and repair of severed axons. This section covers the commonly modeled physiological structures of the brain and central nervous system including the blood-brain barrier (BBB) and nerves stemming from the brain and spinal cord.

The BBB is a well-studied physiological structure in the brain due to its relevance to drug delivery and toxicity [110, 111]. The barrier involves a vascular endothelial layer that overexpresses tight junctions to restrict permeability of blood-borne molecules into the surrounding brain tissue [112]. This endothelial layer directly interacts with astrocytes and indirectly with pericytes and neurons. Extensive work has been published regarding devices mimicking the BBB and several reviews of these systems are available [110, 111, 113–115]. One model of the BBB filled parallel channels with collagen hydrogels containing astrocytes and neurons next to an endothelium-lined channel [116]. This device maintained the cell-specific morphology and function for each cell type. Similar work has aimed to increase physiological relevance by introducing reprogrammed iPSCs to obtain brain microvasculature ECs [117] and perfusing cell-type specific media to maintain cell properties [118]. A recent advance is the incorporation of microvasculature, self-assembled through a co-culture of endothelial cells, astrocytes, and pericytes in a fibrin hydrogel [119]. Gene expression was studied in the presence and absence of the other cell types. The group demonstrated that co-culture with each cell type significantly increased gene expression in each cell type, suggesting that the device allowed the study of active and representative cells in the device. In addition to systems aiming to maximize physiological relevance, some devices have been designed with scalability and commercial use in mind. Jeong et al developed an array of BBB interfaces using neural ECs and astrocytes [120]. In addition to recreating the barrier, the device incorporated electrical sensors to analyze the connectivity of cells in the endothelial layer; integration of sensors to gather quantitative data in real time is an important aspect of developing devices suitable for commercial use. Interestingly, Emulate, Inc. and Cedars-Sinai Medical Center were recently granted a patent on a BBB device to co-culture endothelial cells, astrocytes, and neurons [121]. While the device does not have the complexity of some other models, it demonstrates that commercial applications require simple, yet representative, systems. Each of these models was validated by the presence of tight junctions, transendothelial electrical resistance (TEER) assays, and analysis of molecular weight selectivity of the barrier. While BBB models alone can provide limited information on the efficacy and safety of drugs, devices integrating the barrier into multi-organ chip devices [122] can produce models that better represent efficacy and toxicity of drugs.

Another type of microfluidic device used to study the brain and nervous system aims to isolate the axon of a neuron from the cell body. Models that isolate the axon are imperative in understanding the cellular processes that occur during signal transduction [123] as the axons of a neuron can extend up to one meter and the microenvironment near the axon terminals will likely differ greatly from that of the cell body and dendrites [124]. The original design for the microfluidic device was published in 2005 by Taylor et al; the system connects two parallel channels 100 µm deep with perpendicular 3 µm channels [125]. While the axons from the neuron can grow through the small channels, fluid cannot be exchanged. This creates two distinct microenvironments: one for the cell body, and another for the terminal axons. Since 2005, this design has been integrated with microelectrode arrays to study the electrophysiology along the length of the axon [126, 127]. This device design is also optimal for studying the generation and repair of axons. A 2010 study conducted by Hellman et al damaged axons using a laser [128]. They then studied the effect of egtazic acid (EGTA), a calcium chelator, on the ability of the axon to resist death and induce repair. They concluded that the sequestration of calcium reduced the extent of axonal injury but slowed the repair of the cell. Further studies with similar methods may provide methods of treating patients with traumatic brain injury or nerve damage.

Several devices have been adapted to study a variety of neurological disorders such as Alzheimer's and Parkinson's Disease. Review articles discussing the use of microfluidics for studying disorders of the central nervous system have been published by Yi et al [108] and Jorfi et al [129]. Recent research has featured an axon-isolating microfluidic device used to study the production and effects of amyloid beta (Aβ) peptides on both the axon terminals and the neuronal body [130]. This study concluded that Aβ peptides were secreted more by the axon compared to the dendritic cell body and hopes to provide a platform for the development of therapeutics based on the new knowledge of amyloid plaque production. A different device was used to study degeneration and inflammation in a 3D co-culture of neurons, astrocytes, and microglia in an Alzheimer's disease environment [131]. The authors were able to recreate the phenomena of microglial recruitment, axonal cleavage, and nitric oxide-induced cell damage. Beyond Alzheimer's disease, systems have been developed for studying Parkinson's disease. One model demonstrated that the addition of α-synuclein induced the formation of Lewy Bodies (pathogenic protein aggregates) which were then propagated amongst neuron bodies to spread disease [132]. A similar device was also used to observe mitochondrial transport across the axon, a phenomena associated with Parkinson's disease [133]. Microfluidic devices have also been used to study amyotrophic lateral sclerosis (ALS) [134], stroke [135], multiple sclerosis (MS) [136], migraines [137], and epilepsy [138].

Use of 3D in vitro neural tissue models recapitulate cell–cell and cell–ECM interactions with a much higher fidelity than 2D culture models [109]. The emergence of bioprinting presents a strategy for creating improved 3D neural tissue models. One application of bioprinting for CNS models is to create neuronal tissues to replace existing 2D and 3D culture systems. In 2018, De La Vega et al bioprinted neural tissue by 3D printing human iPSC (hiPSC)-derived neural progenitor cells (NPCs) (figure 4) [139]. Their printing procedure resulted in high cell viability (~81%) and improved differentiation capacity, compared to previous bioprinting strategies [139]. Results showed that these bioprinted neural tissues expressed neuronal markers, spinal cord motor neuron markers, and mature motor neuron markers, demonstrating this strategy's potential as a high-throughput technique for producing hiPSC derived neuronal tissue [139].

Figure 4. Current progress in the microfluidic modeling and bioprinting of neural tissue. (A) Microfluidic platform for modeling the blood brain barrier (BBB). (i) Animation of a perfusable vascular network interacting with astrocytes and neurons in a microfluidic device. (ii) Steps in the self-assembly of the BBB in the perfusable chip. Reproduced from [118]. CC BY 4.0. (B) (i) Schematic representation of Lab-on-a-Printer (LOP)™ printhead and bioprinted neural tissue construct. (ii) Bright field microscopy image of the bioprinted construct consisting of human induced pluripotent stem cell (hiPSC)-derived neural progenitor cells (NPCs) and a fibrin-based bioink. Scale bar represents 3 mm. Reproduced from [139]. CC BY 4.0.

Download figure:

Standard image High-resolution imageAnother interesting application of neural tissue bioprinting is drug development and screening. The identification and validation of drugs for the treatment of Alzheimer's disease is an extremely challenging and expensive process [140]. As the occurrence rate of Alzheimer's disease increases, the need to identify more efficacious drug targets becomes more pressing [140]. Current models and tools for drug identification are lacking and ineffective. To advance the treatment of Alzheimer's, and other diseases, we must develop better strategies to screen drugs before they reach clinical trials. This improvement will save resources, time, and reduce the cost of drug development. 3D bioprinting of neural tissues can be used as a tool for the screening of potential drug candidates and targets [140]. A recent report predicts that 3D bioprinting may provide a solution and serve as an alternate platform for screening and developing Alzheimer's drugs, providing a solution to a progressing problem [140]. This prediction is based on recent research studies [141] and the work summarized in recent reviews [142]. In 2017, Gu et al developed a bioink for the printing and subsequent differentiation of iPSCs [141]. After printing the iPSCs, the authors waited 3 days and then cultured the printed cells in neural induction media for 2–3 weeks, followed by differentiation via media with brain-derived neurotrophic factor [141]. Immunophenotyping was used to confirm the presence of neural markers. The ability to print iPSCs and then differentiate the printed cells into specific lineages presents a huge step in the development of models for the study of disease and for drug development and screening [141].

To our knowledge, there have not been studies that combine 3D bioprinting and organ-on-chip for the creation of neural tissue models. However, despite the scarcity of research in this space, we predict that these two technologies, when combined, may generate improved models. As discussed above, on-chip CNS models provide improved physiological relevance and recapitulate crucial features of the cell microenvironment, such as perfusion, as well as allowing for advanced features, such as sensor integration, which vastly improve data collection. On the other hand, 3D bioprinting provides a fast, accurate method for creating complex neural tissues. In the future, more advanced models, such as that for Alzheimer's study and drug development, will emerge. Such studies will greatly contribute to our understanding of the CNS and provide improved preclinical models, improving healthcare greatly. Progress in organ-on-chip and bioprinted models of brain is summarized in table 4.

Table 4. Summary of progress related to neural tissue.

| Reference | Description | Major advance |

|---|---|---|

| Neural tissue-on-chip (without bioprinting) | ||

| Ma et al [111] | Astrocytes and endothelial cells were cultured on either side of nanofabricated porous silicon nitride membranes | Despite observing contact through large membrane pores, the membranes failed to beat commercially available alternatives in forming ultra-tight junctions |

| Adriani et al [116] | Co-cultured astrocytes and neurons seeded in adjacent collagen matrices next to an endothelial cell-lined channel | Observed restrictive endothelial barrier similar to BBB and neuronal outgrowth through collagen |

| Wang et al [117] | Cultured astrocytes and induced pluripotent stem cell (iPSC)-derived brain microvascular endothelial cells (BMECS) on opposite sides of a porous membrane in a pumpless microfluidic device | Near in vivo permeability was observed through transepithelial/transendothelial electrical resistance (TEER) and molecule permeability analysis |

| Bang et al [118] | Vasculature self-assembled in a fibrin matrix with adjacent neurons and astrocytes forming the blood brain barrier (BBB) | Barrier function was improved by supplying each cell type with a corresponding optimized media |

| Campisi et al [119] | Co-cultured astrocytes, pericytes, and iPSC-derived endothelial cells in a fibrin matrix | Observed self-assembly of vasculature and physiologically representative selective BBB |

| Jeong et al [120] | Integrated electrical sensors to perform on-chip TEER measurements across an astrocyte-endothelial interface along a polycarbonate membrane | Designed chip to have integrated analytical methods to study barrier function |

| Kerns et al [121] | Patented a device containing BMECSs cultured on a membrane | Demonstrated commercial interest in applying organ-on-chip systems for patient care |

| Pinto et al [123] | Used axon-isolating chip to study the ubiquitin-proteasome system | Proteasome inhibition facilitated synaptogenic response by axons |

| Taylor et al [125] | Seeded neurons in one channel and allowed axons to pass through 3 µm channels to a secondary media reservoir | Allowed the isolation of the neuronal cell body from the terminal axons |

| Habibey et al [126] | Adapted axon-isolating chip design for integration with microelectrode arrays aligned with the axon channels for signal transduction monitoring | Integrated electrical sensors for real-time signal monitoring |

| Moutaux et al [127] | Incorporated axonal and postsynaptic electrodes into an axon-isolating microfluidic device | Used in tandem with video processing to understand intracellular dynamics of signal transduction |

| Hellman et al [128] | Used a laser to induce axonal injury in an axon-isolating microfluidic chip | Observed that calcium sequestration reduces the extent of cell injury, but also slows cellular repair |

| Li et al [130] | Adapted axon-isolating device to create chemotactic gradients for studying neuronal production and susceptibility to amyloid beta plaques | Results suggested a localized mechanism for the production of, and toxicity to, amyloid beta plaques |

| Park et al [131] | Neurons, astrocytes, and microglia seeded in Matrigel were maintained in a microfluidic device to recreate an Alzheimer's disease microenvironment | Hallmarks of the disease, such as microglial recruitment, axonal cleavage, and nitric oxide-induced damage, were recapitulated in vitro |

| Volpicelli-Daley et al [132] | Adopted axon-isolating chip to study the creation of Lewy bodies resulting from alpha-synuclein | Used to emulate Parkinson's disease in vitro |

| Lu et al [133] | Used axon-isolating chip to observe transport of mitochondria in axon | Imaged mitochondrial transfer, a component of neurodegenerative disease |

| Kunze et al [134] | Performed astrocyte-neuron co-culture in axon-isolating device | Observed decreased neuron viability in the presence of mutant astrocytes mimicking amyotrophic lateral sclerosis (ALS) |

| Samson et al [135] | Modeled stroke damage in an axon-isolating culture model | Demonstrated that networks of neurons can help inhibit spreading of excitotoxic signals |

| Hosmane et al [136] | Co-cultured neurons and microglia in an axon-isolating device to develop nerve bundles as a model of nervous system injury | Elucidated the mechanism of signaling leading to the phagocytosis of axon terminals |

| Tang et al [137] | Developed a device to perfuse brain slices and deliver local chemical stimuli | Developed a method of localizing chemical stimulation to a region of a brain slice |

| Hill et al [138] | Analyzed brain slices laid across a multi-electrode array | Used system to study the origin and propagation of epileptiform brain signals |

| Bioprinted neural tissue | ||

| De la Vega et al [139] | Used a microfluidic bioprinting method to print iPSC-derived NPCs in a fibrinogen/alginate bioink | Method yields 3D structures of iPSC-derived neural tissue |

| Gu et al [140] | Uses extrusion-based bioprinting to construct scaffolds composed of iPSCs seeded in an alginate-agarose-carboxymethyl chitosan bioink | Exhibited the ability to yield porous homogenous structures of migratory neurons and neuroglia or the formation of embryoid bodies composed of each of the three germ layers |

Lung

The human lung serves as an interface between the human body and the environment, acting as an entry portal for vapors, airborne particles, and aerosols. Epithelial tissue barriers protect the body from allergens, air contaminants, and infectious agents. Despite the presence of these tissue barriers, incidence of respiratory diseases are still prominent ailments [143, 144]. In the last few years, researchers have attempted to elucidate the mechanisms through which antigens avoid these barriers; therefore, many alternative cellular models have been established [145]. Lung-on-chip systems allow for more precise control of the cellular microenvironment and recapitulate in vivo biochemical contexts better than other in vitro models, or even traditional in vivo animal models.

In one study, Huh et al developed a multifunctional microdevice that reconstituted responses to bacterial and inflammatory cytokines, on the organ level, as well mechanical activity on a chip [146]. This was accomplished using two side-by-side microchannels, filled respectively with alveolar epithelial and microvascular ECs, separated by a thin porous membrane. Using vacuum chambers, they performed cyclic stretching on the interface, simulating the motions of breathing. In their device, the cells remained viable for more than two weeks. The incorporation of air in the upper chamber increased the production of surfactant by the epithelial cells, stabilizing the thin liquid layer, as is seen in vivo, eliminating drying. In addition, the authors also identified an increase in the electrical resistance across the two tissue layers and an improvement in the function of relative barrier function, compared to cells cultured in traditional 2D platforms. The cyclic strain application also induced alignment in the cells in the endothelial layer and thereby mimicked the physiological responses previously observed in living blood vessels. The stretching system integrated into the device is unique as it allowed cyclic mechanical stimulation while fluid shear stress was applied to two cell layers. Additionally, this stimulation mechanism did not interfere with the analysis of barrier function (permeability and transport) in the tissue.

More recently, Humayun et al reported a thermoplastic, microfluidic lung-on-chip model that captured both the microenvironment of lung tissue and the interactions between SMCs, ECs, and supporting ECM [147]. The device was constructed from acrylic and consisted of three vertical microfluidic chambers: a lower reservoir containing media for SMC culture, a middle layer of hydrogel, and an upper chamber to achieve air–liquid interface epithelium culture. A Matrigel and type I collagen mixture was found to promote adhesion and monolayer formation in ECs, as well as SMC adhesion and alignment. The primary utilities of the device were long-term SMC–EC co-culture, the ability to perform immunofluorescence staining on chip, the ability to handle samples without disruption of the matrix or cells, and the ability to perform high-throughput studies.

In 2018, Wang et al developed an improved in vitro model of lung cancer using low-temperature molding and 3D bioprinting [148]. With these two biological manufacturing techniques, they fabricated a hydrogel grid scaffold using a suspension comprised of gelatin-sodium alginate and lung cancer cells. The cells in this scaffold were homogenously distributed and exhibited high viability and culture sustainably. The results showed that this model could be cultured and maintain its structural integrity for 28 days. Moreover, histology, gene analysis, and scratch testing showed enhanced invasion and migration capability in the 3D printed cells, when compared to 2D cultured cells. Cell viability after the printing process remained over 90%, showing that the temperature and pressure changes the cells encountered during the 3D printing process caused little damage. Additionally, cells in this model had more cell–cell contacts than 2D cultured cells, indicating increased intercellular interactions and communication, as observed by scanning electron microscopy. They observed no significant differences between the 3D bioprinted and 2D cultured cells, for both the A549 and 95-D cell lines, after 28 days. However, for both cell types, after 8 days, the proliferation rate in 3D culture increased and in the 2D cultured cells declined. Cells cultured in 3D had significantly increased proliferation, while the 2D cultured cells declined after 8 days. The proliferation rate of the 3D cultured cells reached a maximum peak from day 12 to 14, declining after the 14th day. This microdevice successfully reconstituted key features of the alveolar-capillary interface in the human lung and provides the groundwork for further advances to form a larger working model.

3D bioprinting enables automated fabrication of tissue structures and facilitates precise deposition of cells, mimicking the cellular arrangement of native tissue [149]. By using bioprinting tools, Horváth et al engineered an in vitro lung-on-chip [150]. The human air-blood barrier analogue system was created using a layer-by-layer 3D printing approach and was comprised of alveolar epithelial type II and endothelial cells, separated by a thin membrane matrix. The goal of this work was to use valve-based bioprinting to fabricate a complex 3D air-blood tissue barrier in a layer-by-layer process. The resulting engineered lung tissue closely recapitulated the human air-blood barrier. The authors performed comparative studies between manually seeded and bioprinted cultures, looking at cellular morphology and intercellular contacts. The results demonstrated the production of an optimal air-blood tissue barrier construct and an optimized, reproducible fabrication technique.

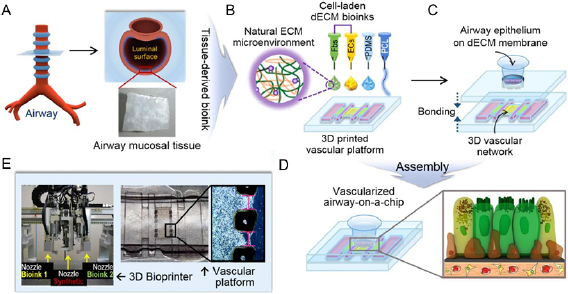

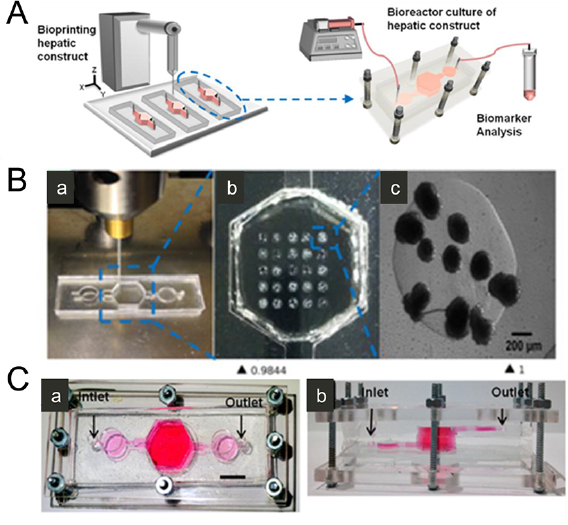

Furthermore, to improve the reproducibility of bioprinted lung-on-chip fabrication, one-step 3D cell printing processes have been developed, creating platforms with complex 3D cellular structures [151]. Following this approach, Park et al fabricated a vascularized lung-on-chip via 3D cell printing (figure 5) [152]. The integrated platform developed was comprised of a 3D printed vascular platform of cell-laden ECM bioinks, integrated with an airway epithelium model. This platform was used to recapitulate inflammatory response and simulate pathophysiology. This lung-on-chip faithfully recapitulated functional lung tissue microstructure, along with its vascular network, reinforcing the promising applications of 3D bioprinted lung-on-chip and motivating further study. Progress in organ-on-chip and bioprinted models of lung is summarized in table 5.

Figure 5. A functional airway-on-chip produced using 3D bioprinting. (A) Decellularized airway mucosal tissue was harvested from the luminal surface of the trachea. (B) The harvested tissue was used to create a printable bioink seeded with fibroblasts and vascular endothelial cells. (C) Airway epithelial cells seeded on a decellularized extracellular matrix (dECM) to create an interface between the tracheal epithelium and vascular endothelium. (D) Animation of the interface between fibroblasts, vascular endothelial, and airway cells on a dECM membrane. (E) A multi-head bioprinter was used to load the microfluidic device with the cell-laden bioinks. Reproduced from [152]. © IOP Publishing Ltd. All rights reserved.

Download figure:

Standard image High-resolution imageTable 5. Summary of progress related to lungs.

| Reference | Description | Major advance |

|---|---|---|

| Lung-on-chip (without bioprinting) | ||

| Huh et al [146] | Constructed a four-chamber microfluidic device with an alveolar epithelium and vascular endothelium interface | The mechanically active device recapitulated in vivo response to bacterial insult and inflammation |

| Humayun et al [147] | Generated a blood-air interface by seeding endothelial and SMCs on either side of a collagen/Matrigel suspended hydrogel | Enabled cell maintenance for more than 31 d with expression of in vivo morphological markers of ECs and SMCs |

| Bioprinted lung | ||

| Wang et al [148] | Used low-temperature molding and 3D bioprinting to create a gelatin/sodium alginate hydrogel seeded with lung cancer cells | Demonstrated that the 3D lung cancer cells were more prone to migration and invasion than their 2D analogs |

| Horváth et al [150] | Bioprinted a Matrigel-separated bilayer of endothelial and lung ECs in a transwell dish | Created homogenous cell layers through automated 3D bioprinting to mimic the air-blood barrier |

| Lung-on-chip (with 3D bioprinting) | ||

| Park et al [152] | Printed endothelial cells seeded in tracheal mucosa extracellular matrix (ECM) in a polycaprolactone (PCL) device | Native ECM drove the self-assembly of a vascular network and recreated asthamatic inflammation in vitro |

Heart

The heart is a vital organ that pumps blood through the vascular system to nourish the tissues and organs of the body and maintain homeostasis. Worldwide, heart disease is the leading cause of death in both men and women [153]. Heart disease encompasses a variety of cardiovascular conditions and usually can be managed with lifestyle changes, medication, or implantable medical devices [154]. Severe heart diseases are resistant to typical treatment methods and may require surgery to repair defects or transplant the heart altogether and, like other transplantable organs, demand greatly exceeds supply [155]. Due to the ubiquity of the problem, a tremendous effort has been made to engineer functional cardiac tissue for heart regeneration [156–159].

The heart also has implications in the development and prescription of drugs. Approximately one third of safety-based pharmaceutical withdrawals are due to cardiotoxicity [6, 7]. Cardiotoxicity is a great concern as it can lead to arrythmia and eventual heart failure. These abnormalities are especially common with anti-cancer drugs [160, 161]. Conventional 2D in vitro and animal models do not adequately mimic the biology and physiology of the human myocardium [162]. Animal models are insufficient for cardiotoxicity studies as they are expensive, time-consuming, and unrepresentative of drug response due to interspecies variation [163, 164]. The lack of representative models of drug response has created an urgent need for high-throughput in vitro systems that can predict the physiological response to therapeutics.