A Systematic Literature Review on Packaging Sustainability: Contents, Opportunities, and Guidelines

Abstract

:1. Introduction

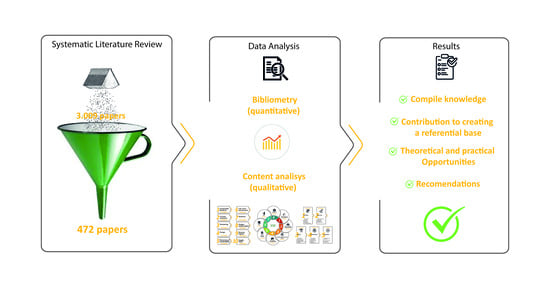

2. Materials and Methods

2.1. Systematic Literature Review

2.2. Content Analysis

3. Results

3.1. Bibliographic Analysis

3.2. Content Analysis

3.2.1. Categories for Classification of the Articles Analyzed

3.2.2. Categories in the Context of Sustainability

(Op#1) The packaging should be planned in a systemic perspective over the entire life cycle (including production, transportation, etc.) and analyzed in terms of environmental impact on a case-to-case basis to meet circular economy objectives.

(Op#2) Life cycle cost (LCC) seems to be an important alternative to reduce costs throughout the value chain and an opportunity to complement LCA studies on packaging in the context of circular economy.

(Op#3) The following gaps in this research area should be studied: (i) the lack of tools and approaches to properly design and adapt food packaging to food needs; (ii) mathematical simulation, based on modeling of mass transfer and reactions into food/packaging systems.[59]

(Op#4) Frameworks/methods may be developed to support researchers in circular economy studies. Frameworks must clearly define the following aspects: (i) the function of packaging (primary, secondary, tertiary), the portion of the chain (pre-consumption or post-consumption), and if the reverse flows of the package include the product itself or not.

(Op#5) To improve the circular flows of materials recovered after use, it is recommended to develop and promote collaborations with third-party organizations beyond the boundaries of the focal company’s operations, including the cascading of materials into supply chains.

(Op#6) Jerzyk [13] argued that manufacturers seek solutions on the market, which are often based on intuition rather than knowledge. This finding reveals an opportunity to approximate the academic community to the manufacturers and developers of packaging.

(Op#7) Articles focusing on the design category have emphasized functions, communication, labeling, and structure to achieve environmental requirements. The focus remains on the environmental aspect, so there is opportunity for social and economic investigations.

(Op#8) Considering contexts such as the health products, in which the elimination of packaging is not feasible, researchers have recommended the creation of global policies on the use and disposal of packaging materials and the education of consumers.[69]

(Op#9) The joint interest of public and private sectors can boost studies on product-service impact and unveil novel alternatives to reduce the environmental impacts of packaging systems.[70]

(Op#10) Concerns about the environment and consumers’ health are two major reasons for buying food products with ecologically sustainable packaging.[12]

(Op#11) Consumers often make their first judgments about brands and products based on their packages, but brands recognized for following environmental and ethical principles are usually better valued by consumers.[90]

(Op#12) The development of biocomposite materials from renewable resources is an attractive alternative to substitute synthetic and non-biodegradable plastics.[98]

(Op#13) With the advances in the packaging industry, packages could be engineered as easy-to-open, resealable, active, as well as intelligent with the incorporation of sensory elements, while still offering the desired barrier properties against oxygen and water vapor. They could be even engineered to provide nutraceuticals to food, or antioxidant, antimicrobial, or antifungal protection to packaged food.[100]

(Op#14) The collaboration between the bioplastic packaging producers and the product manufacturers should, therefore, improve product functionality and innovation in packaging technologies.[102]

(Op#15) Due to the growing interest of consumers in consuming fresh products with extended shelf life and controlled quality, manufacturers must provide modern and safe packaging. Active packaging is a promising solution for this.

(Op#16) Decision-making through mathematical methods leads to fewer costs, time, and involved risks when compared to the real implementation of RL packaging. Therefore, mathematical models can be used to analyze the supply chain.

(Op#17) The performance analysis of new packages for RL should be conducted together with techniques such as life cycle assessment (LCA) to compare the scenario with new and former packages.

(Op#18) Storage space utilization and conveying information are important in packaging design due to their impact on packaging logistics and other aspects of the supply chain system.

3.2.3. Packaging Life Cycle Stages as Context Units

(Op#19) Researchers should emphasize formal methods to develop tools that support packaging professionals to integrate the information from life cycle stages in the phases of packaging design.

3.2.4. Packaging Design Phases as Context Units

4. Triangulation of Categories and the Two Units of Analysis—Practical Implications

4.1. Insights and Guidelines for Practitioners

5. Final Considerations

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Do Amaral Gurgel, F. Administração de Embalagens, 1st ed.; Thomson: São Paulo, Brazil, 2007. [Google Scholar]

- Mestriner, F. Design de Embalagem: Curso Básico, 1st ed.; Pearson Makron Books: São Paulo, Brazil, 2002. [Google Scholar]

- Moura, R.A.; Banzato, J.M. Moura & Banzato Embalagem, Unitização e Conteinerização, 2nd ed.; IMAM: São Paulo, Brazil, 1997. [Google Scholar]

- Boz, Z.; Korhonen, V.; Sand, C.K. Consumer Considerations for the Implementation of Sustainable Packaging: A Review. Sustainability 2020, 12, 2192. [Google Scholar] [CrossRef] [Green Version]

- de Koeijer, B.; de Lange, J.; Wever, R. Desired, Perceived, and Achieved Sustainability: Trade-Offs in Strategic and Operational Packaging Development. Sustainability 2017, 9, 1923. [Google Scholar] [CrossRef] [Green Version]

- Dharmadhikari, S. Eco-Friendly Packaging in Supply Chain. IUP J. Supply Chain. Manag. 2012, 9, 7–19. [Google Scholar]

- Smithers. Available online: https://www.smithers.com/services/market-reports/packaging/future-of-global-packaging-to-2024 (accessed on 30 September 2020).

- WPO. World Packaging Organization. Available online: https://www.worldpackaging.org (accessed on 30 September 2020).

- Mintel. Available online: https://www.mintel.com/global-packaging-trends (accessed on 30 September 2020).

- Lu, S.; Yang, L.; Liu, W.; Jia, L. User preference for electronic commerce overpackaging solutions: Implications for cleaner production. J. Clean. Prod. 2020, 258, 120936. [Google Scholar] [CrossRef]

- Ellen Macarthur Foundation. Available online: http://www.ellenmacarthurfoundation.com (accessed on 25 September 2020).

- Petljak, K.; Naletina, D.; Bilogrević, K. Considering ecologically sustainable packaging during decision-making while buying food products. Èkon. Poljopr. 2019, 66, 107–126. [Google Scholar] [CrossRef] [Green Version]

- Jerzyk, E. Design and Communication of Ecological Content on Sustainable Packaging in Young Consumers’ Opinions. J. Food Prod. Mark. 2016, 22, 707–716. [Google Scholar] [CrossRef]

- Tirpude, R.; Alam, T.; Saha, N.C. Effect of Package Design of Handloom Products to Influence Consumer Perception. J. Packag. Technol. Res. 2019, 3, 169–179. [Google Scholar] [CrossRef]

- Elhussieny, A.; Faisal, M.; D’Angelo, G.; Aboulkhair, N.T.; Everitt, N.M.; Fahim, I.S. Valorisation of shrimp and rice straw waste into food packaging applications. Ain Shams Eng. J. 2020, 11, 1219–1226. [Google Scholar] [CrossRef]

- Thomopoulos, R.; Baudrit, C.; Boukhelifa, N.; Boutrou, R.; Buche, P.; Guichard, E.; Guillard, V.; Lutton, E.; Mirade, P.S.; Ndiaye, A.; et al. Multi-Criteria Reverse Engineering for Food: Genesis and Ongoing Advances. Food Eng. Rev. 2019, 11, 44–60. [Google Scholar] [CrossRef] [Green Version]

- Al-Tayyar, N.A.; Youssef, A.M.; Al-Hindi, R. Antimicrobial food packaging based on sustainable Bio-based materials for reducing foodborne Pathogens: A review. Food Chem. 2020, 310, 125915. [Google Scholar] [CrossRef]

- Cazón, P.; Vázquez, M. Mechanical and barrier properties of chitosan combined with other components as food packaging film. Environ. Chem. Lett. 2019, 18, 257–267. [Google Scholar] [CrossRef]

- Paiano, A.; Crovella, T.; Lagioia, G. Managing sustainable practices in cruise tourism: The assessment of carbon footprint and waste of water and beverage packaging. Tour. Manag. 2019, 77, 104016. [Google Scholar] [CrossRef]

- Avella, M.; Bonadies, E.; Martuscelli, E.; Rimedio, R. European current standardization for plastic packaging recoverable through composting and biodegradation. Polym. Test. 2001, 20, 517–521. [Google Scholar] [CrossRef]

- Barkoula, N.M.; Alcock, B.; Cabrera, N.O.; Peijs, T. Flame-Retardancy Properties of Intumescent Ammonium Poly(Phosphate) and Mineral Filler Magnesium Hydroxide in Combination with Graphene. Polym. Polym. Compos. 2008, 16, 101–113. [Google Scholar] [CrossRef]

- Davis, G.; Song, J. Biodegradable packaging based on raw materials from crops and their impact on waste management. Ind. Crop. Prod. 2006, 23, 147–161. [Google Scholar] [CrossRef]

- Kuorwel, K.K.; Cran, M.J.; Sonneveld, K.; Miltz, J.; Bigger, S.W. Antimicrobial Activity of Biodegradable Polysaccharide and Protein-Based Films Containing Active Agents. J. Food Sci. 2011, 76, R90–R102. [Google Scholar] [CrossRef] [Green Version]

- Stark, N.M. Opportunities for Cellulose Nanomaterials in Packaging Films: A Review and Future Trends. J. Renew. Mater. 2016, 4, 313–326. [Google Scholar] [CrossRef]

- James, K. Environmental life cycle costs in the Australian food packaging supply chain. Soc. Environ. Account. J. 2003, 23, 12–13. [Google Scholar] [CrossRef]

- Rhim, J.-W.; Park, H.-M.; Ha, C.-S. Bio-nanocomposites for food packaging applications. Prog. Polym. Sci. 2013, 38, 1629–1652. [Google Scholar] [CrossRef]

- Russell, D.A. Sustainable (food) packaging—An overview. Food Addit. Contam. Part A 2014, 31, 396–401. [Google Scholar] [CrossRef]

- Sung, S.-Y.; Sin, L.T.; Tee, T.-T.; Bee, S.-T.; Rahmat, A.R.; Rahman, W.; Tan, A.-C.; Vikhraman, M. Antimicrobial agents for food packaging applications. Trends Food Sci. Technol. 2013, 33, 110–123. [Google Scholar] [CrossRef]

- Vanderroost, M.; Ragaert, P.; Devlieghere, F.; De Meulenaer, B. Intelligent food packaging: The next generation. Trends Food Sci. Technol. 2014, 39, 47–62. [Google Scholar] [CrossRef]

- Bailey, I. Principles, Policies and Practice: Evaluating the Environmental Sustainability of Britain’s Packaging Regulations. Sustain. Dev. 2000, 8, 51–64. [Google Scholar] [CrossRef]

- Brisson, I. Packaging waste and the environment: Economics and policy. Resour. Conserv. Recycl. 1993, 8, 183–292. [Google Scholar] [CrossRef]

- Chen, F.; Chen, H.; Yang, J.; Long, R.; Li, W. Impact of regulatory focus on express packaging waste recycling behavior: Moderating role of psychological empowerment perception. Environ. Sci. Pollut. Res. 2019, 26, 8862–8874. [Google Scholar] [CrossRef] [PubMed]

- Sinclair, A.; Fenton, R. Stewardship for packaging and packaging waste: Key policy elements for sustainability. Can. Public Adm. 1997, 40, 123–148. [Google Scholar] [CrossRef]

- Song, Q.; Li, J.; Zeng, X. Minimizing the increasing solid waste through zero waste strategy. J. Clean. Prod. 2015, 104, 199–210. [Google Scholar] [CrossRef]

- Bucci, D.Z.; Forcellini, F.A. Sustainable Packaging Design Model. In Complex Systems Concurrent Engineering; Springer: London, UK, 2007; pp. 363–370. [Google Scholar] [CrossRef]

- Davison, L.; Redhill, D. Structural packaging design: Building and protecting brand value. J. Brand Manag. 1998, 6, 13–26. [Google Scholar] [CrossRef]

- De Pelsmacker, P.; Janssens, W.; Sterckx, E.; Mielants, C. Consumer preferences for the marketing of ethically labelled coffee. Int. Mark. Rev. 2005, 22, 512–530. [Google Scholar] [CrossRef]

- Jimenez, J.F.; Gázquez-Abad, J.C.; Ceballos-Santamaría, G. Innovation in eco-packaging in private labels. Innovation 2015, 17, 81–90. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Banerjee, A.; Saurabh, C.K.; Tye, Y.Y.; Suriani, A.B.; Mohamed, A.; Karim, A.A.; Rizal, S.; Paridah, M.T. Biodegradable Films for Fruits and Vegetables Packaging Application: Preparation and Properties. Food Eng. Rev. 2018, 10, 139–153. [Google Scholar] [CrossRef]

- Besier, S. Generational perceptions of pro-environmental packaging advantages. uwf UmweltWirtschaftsForum 2015, 23, 315–322. [Google Scholar] [CrossRef]

- Casarejos, F.; Bastos, C.R.; Rufin, C.; Frota, M.N. Rethinking packaging production and consumption vis-à-vis circular economy: A case study of compostable cassava starch-based material. J. Clean. Prod. 2018, 201, 1019–1028. [Google Scholar] [CrossRef]

- De Campos, E.A.R.; De Paula, I.C.; Pagani, R.N.; Guarnieri, P. Reverse logistics for the end-of-life and end-of-use products in the pharmaceutical industry: A systematic literature review. Supply Chain Manag. Int. J. 2017, 22, 375–392. [Google Scholar] [CrossRef]

- Mostacedo, B.; Fredericksen, T.S. Manual de Métodos Básicos de Muestreoy Análisis en Ecología Vegetal; Nash, D., Ed.; Editora El.: Santa Cruz, Bolivia, 2000; ISBN 9780874216561. [Google Scholar]

- Maxwell, J. Designing a Qualitative Study; SAGE: Thousand Oaks, CA, USA, 2009; pp. 214–253. [Google Scholar] [CrossRef] [Green Version]

- Moraes, R. Análise de conteúdo. Educação 1999, 22, 7–32. [Google Scholar]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; PRISMA Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [Green Version]

- Guarnieri, P.; Streit, J.A.C.; Batista, L.C. Reverse logistics and the sectoral agreement of packaging industry in Brazil towards a transition to circular economy. Resour. Conserv. Recycl. 2019, 153, 104541. [Google Scholar] [CrossRef]

- Jang, Y.-C.; Lee, G.; Kwon, Y.; Lim, J.-H.; Jeong, J.-H. Recycling and management practices of plastic packaging waste towards a circular economy in South Korea. Resour. Conserv. Recycl. 2020, 158, 104798. [Google Scholar] [CrossRef]

- European Commission. An EU Action Plan for the Circular Economy. COM. 2015, p. 614. Available online: https://www.eea.europa.eu/policy-documents/com-2015-0614-final (accessed on 15 December 2018).

- Abuabara, L.; Paucar-Caceres, A.; Burrowes-Cromwell, T. Consumers’ values and behaviour in the Brazilian coffee-in-capsules market: Promoting circular economy. Int. J. Prod. Res. 2019, 57, 7269–7288. [Google Scholar] [CrossRef]

- Buil, P.; Roger-Loppacher, O.; Selvam, R.M.; Prieto-Sandoval, V. The Involvement of Future Generations in the Circular Economy Paradigm: An Empirical Analysis on Aluminium Packaging Recycling in Spain. Sustainability 2017, 9, 2345. [Google Scholar] [CrossRef] [Green Version]

- Niero, M.; Kalbar, P.P. Coupling material circularity indicators and life cycle based indicators: A proposal to advance the assessment of circular economy strategies at the product level. Resour. Conserv. Recycl. 2018, 140, 305–312. [Google Scholar] [CrossRef]

- Marrucci, L.; Marchi, M.; Daddi, T. Improving the carbon footprint of food and packaging waste management in a supermarket of the Italian retail sector. Waste Manag. 2020, 105, 594–603. [Google Scholar] [CrossRef] [PubMed]

- Niero, M.; Olsen, S.I. Circular economy: To be or not to be in a closed product loop? A Life Cycle Assessment of aluminium cans with inclusion of alloying elements. Resour. Conserv. Recycl. 2016, 114, 18–31. [Google Scholar] [CrossRef] [Green Version]

- Civancik-Uslu, D.; Puig, R.; Voigt, S.; Walter, D.; Fullana-I-Palmer, P. Improving the production chain with LCA and eco-design: Application to cosmetic packaging. Resour. Conserv. Recycl. 2019, 151, 104475. [Google Scholar] [CrossRef]

- Schmidt Rivera, X.C.; Leadley, C.; Potter, L.; Azapagic, A. Aiding the Design of Innovative and Sustainable Food Packaging: Integrating Techno-Environmental and Circular Economy Criteria. Energy Procedia 2019, 161, 190–197. [Google Scholar] [CrossRef]

- Albuquerque, T.L.; Mattos, C.A.; Scur, G.; Kissimoto, K. Life cycle costing and externalities to analyze circular economy strategy: Comparison between aluminum packaging and tinplate. J. Clean. Prod. 2019, 234, 477–486. [Google Scholar] [CrossRef]

- de la Caba, K.; Guerrero, P.; Trung, T.S.; Cruz-Romero, M.; Kerry, J.P.; Fluhr, J.; Maurer, M.; Kruijssen, F.; Albalat, A.; Bunting, S.; et al. From seafood waste to active seafood packaging: An emerging opportunity of the circular economy. J. Clean. Prod. 2018, 208, 86–98. [Google Scholar] [CrossRef]

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The Next Generation of Sustainable Food Packaging to Preserve Our Environment in a Circular Economy Context. Front. Nutr. 2018, 5, 121. [Google Scholar] [CrossRef] [Green Version]

- Meherishi, L.; Narayana, S.A.; Ranjani, K. Sustainable packaging for supply chain management in the circular economy: A review. J. Clean. Prod. 2019, 237, 117582. [Google Scholar] [CrossRef]

- Batista, L.; Gong, Y.; Pereira, S.; Jia, F.; Bittar, A. Circular supply chains in emerging economies—A comparative study of packaging recovery ecosystems in China and Brazil. Int. J. Prod. Res. 2018, 57, 7248–7268. [Google Scholar] [CrossRef] [Green Version]

- Holdway, R.; Walker, D.; Hilton, M. Eco-design and successful packaging. Des. Manag. J. 2010, 13, 45–53. [Google Scholar] [CrossRef]

- Song, L.; Lim, Y.; Chang, P.; Guo, Y.; Zhang, M.; Wang, X.; Yu, X.; Lehto, M.R.; Cai, H. Ecolabel’s role in informing sustainable consumption: A naturalistic decision making study using eye tracking glasses. J. Clean. Prod. 2019, 218, 685–695. [Google Scholar] [CrossRef]

- Buelow, S.; Lewis, H.; Sonneveld, K. The role of labels in directing consumer packaging waste. Manag. Environ. Qual. Int. J. 2010, 21, 198–213. [Google Scholar] [CrossRef] [Green Version]

- Ma, X.; Moultrie, J. What Stops Designers from Designing Sustainable Packaging?—A Review of Eco-Design Tools with Regard to Packaging Design. In Sustainable Design and Manufacturing 2017, Smart Innovation, Systems and Technologies; Springer: Cham, Swizterland, 2017; Volume 3, p. 11. [Google Scholar] [CrossRef]

- Rodríguez-Parada, L.; Mayuet, P.F.; Gámez, A.J. Custom Design of Packaging through Advanced Technologies: A Case Study Applied to Apples. Materials 2019, 12, 467. [Google Scholar] [CrossRef] [Green Version]

- Desai, A.; Mukherji, A. The evolution of vertically integrated organizations: The role of historical context. Manag. Decis. 2001, 39, 233–243. [Google Scholar] [CrossRef]

- da Cruz, N.; Simões, P.; Marques, R.C. Economic cost recovery in the recycling of packaging waste: The case of Portugal. J. Clean. Prod. 2012, 37, 8–18. [Google Scholar] [CrossRef] [Green Version]

- Gurtu, A.; Arendt, J.D. Packaging, business, and society. Int. J. Nonprofit Volunt. Sect. Mark. 2019, 25, e1670. [Google Scholar] [CrossRef]

- Barros, M.V.; Salvador, R.; Piekarski, C.M.; de Francisco, A.C. Mapping of main research lines concerning life cycle studies on packaging systems in Brazil and in the world. Int. J. Life Cycle Assess. 2018, 24, 1429–1443. [Google Scholar] [CrossRef]

- Wikström, F.; Verghese, K.; Auras, R.; Olsson, A.; Williams, H.; Wever, R.; Grönman, K.; Pettersen, M.K.; Møller, H.; Soukka, R. Packaging Strategies That Save Food: A Research Agenda for 2030. J. Ind. Ecol. 2018, 23, 532–540. [Google Scholar] [CrossRef]

- Niero, M.; Negrelli, A.J.; Hoffmeyer, S.B.; Olsen, S.I.; Birkved, M. Closing the loop for aluminum cans: Life Cycle Assessment of progression in Cradle-to-Cradle certification levels. J. Clean. Prod. 2016, 126, 352–362. [Google Scholar] [CrossRef] [Green Version]

- Early, C.; Kidman, T.; Menvielle, M.; Geyer, R.; McMullan, R. Informing Packaging Design Decisions at Toyota Motor Sales Using Life Cycle Assessment and Costing. J. Ind. Ecol. 2009, 13, 592–606. [Google Scholar] [CrossRef]

- Ingrao, C.; Gigli, M.; Siracusa, V. An attributional Life Cycle Assessment application experience to highlight environmental hotspots in the production of foamy polylactic acid trays for fresh-food packaging usage. J. Clean. Prod. 2017, 150, 93–103. [Google Scholar] [CrossRef]

- Pauer, E.; Wohner, B.; Heinrich, V.; Tacker, M. Assessing the Environmental Sustainability of Food Packaging: An Extended Life Cycle Assessment including Packaging-Related Food Losses and Waste and Circularity Assessment. Sustainability 2019, 11, 925. [Google Scholar] [CrossRef] [Green Version]

- Madival, S.; Auras, R.; Singh, S.P.; Narayan, R. Assessment of the environmental profile of PLA, PET and PS clamshell containers using LCA methodology. J. Clean. Prod. 2009, 17, 1183–1194. [Google Scholar] [CrossRef]

- Niero, M.; Hauschild, M.Z.; Hoffmeyer, S.B.; Olsen, S.I. Combining Eco-Efficiency and Eco-Effectiveness for Continuous Loop Beverage Packaging Systems: Lessons from the Carlsberg Circular Community. J. Ind. Ecol. 2017, 21, 742–753. [Google Scholar] [CrossRef]

- Simon, B.; Amor, M.B.; Földényi, R. Life cycle impact assessment of beverage packaging systems: Focus on the collection of post-consumer bottles. J. Clean. Prod. 2016, 112, 238–248. [Google Scholar] [CrossRef]

- Ferrara, C.; De Feo, G. Comparative life cycle assessment of alternative systems for wine packaging in Italy. J. Clean. Prod. 2020, 259, 120888. [Google Scholar] [CrossRef]

- Manfredi, M.; Vignali, G. Comparative Life Cycle Assessment of hot filling and aseptic packaging systems used for beverages. J. Food Eng. 2015, 147, 39–48. [Google Scholar] [CrossRef]

- Wollny, V.; Dehoust, G.; Fritsche, U.R.; Weinem, P. Comparison of Plastic Packaging Waste Management Options: Feedstock Recycling versus Energy Recovery in Germany. J. Ind. Ecol. 2001, 5, 49–63. [Google Scholar] [CrossRef]

- Coelho, P.M.; Corona, B.; ten Klooster, R.; Worrell, E. Sustainability of reusable packaging–Current situation and trends. Resour. Conserv. Recycl. X 2020, 6, 100037. [Google Scholar] [CrossRef]

- Ghimire, S.; Flury, M.; Scheenstra, E.J.; Miles, C.A. Sampling and degradation of biodegradable plastic and paper mulches in field after tillage incorporation. Sci. Total Environ. 2019, 703, 135577. [Google Scholar] [CrossRef] [PubMed]

- Biganzoli, L.; Rigamonti, L.; Grosso, M. LCA evaluation of packaging re-use: The steel drums case study. J. Mater. Cycles Waste Manag. 2018, 21, 67–78. [Google Scholar] [CrossRef]

- Heller, M.C.; Selke, S.E.M.; Keoleian, G.A. Mapping the Influence of Food Waste in Food Packaging Environmental Performance Assessments. J. Ind. Ecol. 2018, 23, 480–495. [Google Scholar] [CrossRef] [Green Version]

- Kardos, M.; Gabor, M.R.; Cristache, N. Green Marketing’s Roles in Sustainability and Ecopreneurship. Case Study: Green Packaging’s Impact on Romanian Young Consumers’ Environmental Responsibility. Sustainability 2019, 11, 873. [Google Scholar] [CrossRef] [Green Version]

- Rundh, B. Linking packaging to marketing: How packaging is influencing the marketing strategy. Br. Food J. 2013, 115, 1547–1563. [Google Scholar] [CrossRef]

- Barber, N. “Green” wine packaging: Targeting environmental consumers. Int. J. Wine Bus. Res. 2010, 22, 423–444. [Google Scholar] [CrossRef]

- Martin, C.R.A. The Effect of Packaging and Brand on Children’s and Parents’ Purchasing Decisions and the Moderating Role of Pester Power. Br. Food J. 2015, 76, 33–64. [Google Scholar] [CrossRef]

- Fernie, J. International Journal of Retail & Distribution Management. Mark. Intell. Plan. 1993, 11, 11–12. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Parker, L.; Brennan, L.; Lockrey, S. A consumer definition of eco-friendly packaging. J. Clean. Prod. 2019, 252, 119792. [Google Scholar] [CrossRef]

- Masmoudi, F.; Alix, S.; Buet, S.; Mehri, A.; Bessadok, A.; Jaziri, M.; Ammar, E. Design and Characterization of a New Food Packaging Material by Recycling Blends Virgin and Recovered polyethylene terephthalate. Polym. Eng. Sci. 2019, 60, 250–256. [Google Scholar] [CrossRef]

- Adel, A.M.; Ibrahim, A.A.; El-Shafei, A.M.; Al-Shemy, M.T. Inclusion complex of clove oil with chitosan/β-cyclodextrin citrate/oxidized nanocellulose biocomposite for active food packaging. Food Packag. Shelf Life 2019, 20, 100307. [Google Scholar] [CrossRef]

- Cacciotti, I.; Mori, S.; Cherubini, V.; Nanni, F. Eco-sustainable systems based on poly(lactic acid), diatomite and coffee grounds extract for food packaging. Int. J. Biol. Macromol. 2018, 112, 567–575. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dieckmann, E.; Nagy, B.; Yiakoumetti, K.; Sheldrick, L.; Cheeseman, C. Thermal insulation packaging for cold-chain deliveries made from feathers. Food Packag. Shelf Life 2019, 21, 100360. [Google Scholar] [CrossRef]

- Ketkaew, S.; Kasemsiri, P.; Hiziroglu, S.; Mongkolthanaruk, W.; Wannasutta, R.; Pongsa, U.; Chindaprasirt, P. Effect of Oregano Essential Oil Content on Properties of Green Biocomposites Based on Cassava Starch and Sugarcane Bagasse for Bioactive Packaging. J. Polym. Environ. 2017, 26, 311–318. [Google Scholar] [CrossRef]

- Pranata, M.P.; González-Buesa, J.; Chopra, S.; Kim, K.; Pietri, Y.; Ng, P.K.W.; Matuana, L.M.; Almenar, E. Egg White Protein Film Production Through Extrusion and Calendering Processes and its Suitability for Food Packaging Applications. Food Bioprocess Technol. 2019, 12, 714–727. [Google Scholar] [CrossRef]

- Iahnke, A.O.E.S.; Costa, T.M.H.; Rios, A.D.O.; Flôres, S.H. Residues of minimally processed carrot and gelatin capsules: Potential materials for packaging films. Ind. Crop. Prod. 2015, 76, 1071–1078. [Google Scholar] [CrossRef]

- Azeredo, H.M.C. de Nanocomposites for Food Packaging Applications. Food Res. Int. 2009, 42, 1240–1253. [Google Scholar] [CrossRef] [Green Version]

- Topuza, F.; Uyarb, T. Antioxidant, antibacterial and antifungal electrospun nanofibers for food packaging applications. Food Res. Int. 2019, 130, 108927. [Google Scholar] [CrossRef]

- Basavegowda, N.; Mandal, T.K.; Baek, K.-H. Bimetallic and Trimetallic Nanoparticles for Active Food Packaging Applications: A Review. Food Bioprocess Technol. 2019, 13, 30–44. [Google Scholar] [CrossRef]

- Liliani; Tjahjono, B.; Cao, D. Advancing Bioplastic Packaging Products through Co-Innovation: A Conceptual Framework for Supplier-Customer Collaboration. J. Clean. Prod. 2020, 252, 119861. [Google Scholar] [CrossRef]

- Lopez-Gomez, A.; Cerdán-Cartagena, F.; Muro, J.S.; Boluda-Aguilar, M.; Hernández-Hernández, M.E.; López-Serrano, M.A.; López-Coronado, J. Radiofrequency Identification and Surface Acoustic Wave Technologies for Developing the Food Intelligent Packaging Concept. Food Eng. Rev. 2014, 7, 11–32. [Google Scholar] [CrossRef]

- Deshwal, G.K.; Panjagari, N.R. Review on metal packaging: Materials, forms, food applications, safety and recyclability. J. Food Sci. Technol. 2019, 57, 2377–2392. [Google Scholar] [CrossRef] [PubMed]

- Wyrwa, J.; Barska, A. Innovations in the food packaging market: Active packaging. Eur. Food Res. Technol. 2017, 243, 1681–1692. [Google Scholar] [CrossRef]

- Silva, D.A.L.; Renó, G.W.S.; Sevegnani, G.; Sevegnani, T.B.; Truzzi, O.M.S. Comparison of disposable and returnable packaging: A case study of reverse logistics in Brazil. J. Clean. Prod. 2013, 47, 377–387. [Google Scholar] [CrossRef]

- Lagarda-Leyva, E.A.; Morales-Mendoza, L.F.; Ríos-Vázquez, N.J.; Ayala-Espinoza, A.; Nieblas-Armenta, C.K. Managing plastic waste from agriculture through reverse logistics and dynamic modeling. Clean Technol. Environ. Policy 2019, 21, 1415–1432. [Google Scholar] [CrossRef]

- Couto, M.C.L.; Lange, L.; Rosa, R.D.A.; Couto, P.R.L. Planning the location of facilities to implement a reverse logistic system of post-consumer packaging using a location mathematical model. Waste Manag. Res. 2017, 35, 1254–1265. [Google Scholar] [CrossRef]

- Li, Z.; Huang, J. How to Effectively Improve Pesticide Waste Governance: A Perspective of Reverse Logistics. Sustainability 2018, 10, 3622. [Google Scholar] [CrossRef] [Green Version]

- Yusuf, Y.Y.; Olaberinjo, A.E.; Papadopoulos, T.; Gunasekaran, A.; Subramanian, N.; Sharifi, H. Returnable transport packaging in developing countries: Drivers, barriers and business performance. Prod. Plan. Control 2017, 28, 629–658. [Google Scholar] [CrossRef]

- Zouari, A. Relationships between eco-design, resources commitment and reverse logistics: Conceptual framework. J. Adv. Mech. Des. Syst. Manuf. 2019, 13, JAMDSM0039. [Google Scholar] [CrossRef] [Green Version]

- Lai, J.; Harjati, A.; McGinnis, L.; Zhou, C.; Guldberg, T. An economic and environmental framework for analyzing globally sourced auto parts packaging system. J. Clean. Prod. 2008, 16, 1632–1646. [Google Scholar] [CrossRef]

- Bortolini, M.; Galizia, F.G.; Mora, C.; Botti, L.; Rosano, M. Bi-objective design of fresh food supply chain networks with reusable and disposable packaging containers. J. Clean. Prod. 2018, 184, 375–388. [Google Scholar] [CrossRef]

- Gardas, B.B.; Raut, R.D.; Narkhede, B. Identifying critical success factors to facilitate reusable plastic packaging towards sustainable supply chain management. J. Environ. Manag. 2019, 236, 81–92. [Google Scholar] [CrossRef]

- Wang, Z.; Mathiyazhagan, K.; Xu, L.; Diabat, A. A decision making trial and evaluation laboratory approach to analyze the barriers to Green Supply Chain Management adoption in a food packaging company. J. Clean. Prod. 2016, 117, 19–28. [Google Scholar] [CrossRef]

- Dahlbo, H.; Poliakova, V.; Mylläri, V.; Sahimaa, O.; Anderson, R. Recycling potential of post-consumer plastic packaging waste in Finland. Waste Manag. 2018, 71, 52–61. [Google Scholar] [CrossRef] [PubMed]

- Monnot, E.; Reniou, F.; Parguel, B.; Elgaaied-Gambier, L. “Thinking Outside the Packaging Box”: Should Brands Consider Store Shelf Context When Eliminating Overpackaging? J. Bus. Ethic 2017, 154, 355–370. [Google Scholar] [CrossRef]

- Babader, A.; Ren, J.; Jones, K.O.; Wang, J. A system dynamics approach for enhancing social behaviours regarding the reuse of packaging. Expert Syst. Appl. 2016, 46, 417–425. [Google Scholar] [CrossRef] [Green Version]

- Mohammadhosseini, H.; Alyousef, R.; Lim, N.H.A.S.; Tahir, M.M.; Alabduljabbar, H.; Mohamed, A.M.; Samadi, M. Waste metalized film food packaging as low cost and ecofriendly fibrous materials in the production of sustainable and green concrete composites. J. Clean. Prod. 2020, 258, 120726. [Google Scholar] [CrossRef]

- Picuno, C.; Godosi, Z.; Kuchta, K.; Picuno, P. Agrochemical plastic packaging waste decontamination for recycling: Pilot tests in Italy. J. Agric. Eng. 2019, 50, 99–104. [Google Scholar] [CrossRef]

- Rigamonti, L.; Biganzoli, L.; Grosso, M. Packaging re-use: A starting point for its quantification. J. Mater. Cycles Waste Manag. 2018, 21, 35–43. [Google Scholar] [CrossRef]

- Ahenkan, A.; Boon, E. Commercialization of Non-Timber Forest Products in Ghana: Processing, Packaging and Marketing. J. Food Agric. Environ. 2010, 8, 962–969. [Google Scholar]

- Almeida, C.M.V.B.; Rodrigues, A.; Bonilla, S.H.; Giannetti, B.F. Emergy as a tool for Ecodesign: Evaluating materials selection for beverage packages in Brazil. J. Clean. Prod. 2010, 18, 32–43. [Google Scholar] [CrossRef]

- Khan, A.; Tandon, P. Realizing the End-of-life Considerations in the Design of Food Packaging. J. Packag. Technol. Res. 2018, 2, 251–263. [Google Scholar] [CrossRef]

- Sarkar, B.; Tayyab, M.; Kim, N.; Habib, M.S. Optimal production delivery policies for supplier and manufacturer in a constrained closed-loop supply chain for returnable transport packaging through metaheuristic approach. Comput. Ind. Eng. 2019, 135, 987–1003. [Google Scholar] [CrossRef]

- Wohner, B.; Schwarzinger, N.; Gürlich, U.; Heinrich, V.; Tacker, M. Technical emptiability of dairy product packaging and its environmental implications in Austria. PeerJ 2019, 7, e7578. [Google Scholar] [CrossRef] [PubMed]

- Hillier, D.; Comfort, D.; Jones, P. The Packaging Industry and Sustainability. Athens J. Bus. Econ. 2017, 3, 405–426. [Google Scholar] [CrossRef] [Green Version]

- Deshwal, G.K.; Panjagari, N.R.; Alam, T. An overview of paper and paper based food packaging materials: Health safety and environmental concerns. J. Food Sci. Technol. 2019, 56, 4391–4403. [Google Scholar] [CrossRef]

- Bergmiller, K.H. Manual Para Planejamento de Embalagens, 1st ed.; MIC-STI/IDI/MAM-RS: Rio de Janeiro, Brazil, 1976. [Google Scholar]

- Brod, M. Desenho de Embalagem: Projeto Mediado Por Parâmetros Ecológicos. Master’s Thesis, Universidade Federal de Santa Maria, Camobi, Brazil, 2004. [Google Scholar]

- Carvalho, M.A. Engenharia de Embalagens: Uma Abordagem Técnica Do Desenvolvimento de Projetos de Embalagem, 1st ed.; Novatec: São Paulo, Brazil, 2008. [Google Scholar]

- Giovannetti, M.D. El Mundo Del Envase: Manual Para El Diseño y Producción de Envases y Embalajes, 2nd ed.; Gustavo Gili: Naucalpan de Juárez, México, 1995. [Google Scholar]

- Negrão, C.; Camargo, E. Design de Embalagens: Do Marketing a Produção; Novatec: São Paulo, Brazil, 2008. [Google Scholar]

- Agarski, B.; Vukelic, D.; Micunovic, M.I.; Budak, I. Evaluation of the environmental impact of plastic cap production, packaging, and disposal. J. Environ. Manag. 2019, 245, 55–65. [Google Scholar] [CrossRef]

- Bozzola, M.; De Giorgi, C. Social packaging. Design for wide sustainability. Des. J. 2019, 22, 737–749. [Google Scholar] [CrossRef] [Green Version]

- Wikström, F.; Williams, H.; Venkatesh, G. The influence of packaging attributes on recycling and food waste behaviour—An environmental comparison of two packaging alternatives. J. Clean. Prod. 2016, 137, 895–902. [Google Scholar] [CrossRef] [Green Version]

- Magnier, L.; Schoormans, J. Consumer reactions to sustainable packaging: The interplay of visual appearance, verbal claim and environmental concern. J. Environ. Psychol. 2015, 44, 53–62. [Google Scholar] [CrossRef]

- Geueke, B.; Groh, K.; Muncke, J. Food packaging in the circular economy: Overview of chemical safety aspects for commonly used materials. J. Clean. Prod. 2018, 193, 491–505. [Google Scholar] [CrossRef]

- Simms, C.; Trott, P.; Hende, E.V.D.; Hultink, E.J. Barriers to the adoption of waste-reducing eco-innovations in the packaged food sector: A study in the UK and the Netherlands. J. Clean. Prod. 2019, 244, 118792. [Google Scholar] [CrossRef] [Green Version]

- Ren, H.; Qiao, F.; Shi, Y.; Knutzen, M.W.; Wang, Z.; Du, H.; Zhang, H. PlantBottle™ Packaging program is continuing its journey to pursue bio-mono-ethylene glycol using agricultural waste. J. Renew. Sustain. Energy 2015, 7, 041510. [Google Scholar] [CrossRef]

- Hariga, M.; Glock, C.; Kim, T. Integrated product and container inventory model for a single-vendor single-buyer supply chain with owned and rented returnable transport items. Int. J. Prod. Res. 2015, 54, 1964–1979. [Google Scholar] [CrossRef]

- Abhijith, R.; Ashok, A.; Rejeesh, C. Sustainable packaging applications from mycelium to substitute polystyrene: A review. Mater. Today Proc. 2018, 5, 2139–2145. [Google Scholar] [CrossRef]

- Lara, C.A.A.; Athès, V.; Buche, P.; Della Valle, G.; Farines, V.; Fonseca, F.; Guillard, V.; Kansou, K.; Kristiawan, M.; Monclus, V.; et al. The virtual food system: Innovative models and experiential feedback in technologies for winemaking, the cereals chain, food packaging and eco-designed starter production. Innov. Food Sci. Emerg. Technol. 2018, 46, 54–64. [Google Scholar] [CrossRef] [Green Version]

- Andersson, H. Nature, nationalism and neoliberalism on food packaging: The case of Sweden. Discourse Context Media 2019, 34, 100329. [Google Scholar] [CrossRef]

- Didone, M.; Tosello, G. Moulded pulp products manufacturing with thermoforming. Packag. Technol. Sci. 2018, 32, 7–22. [Google Scholar] [CrossRef] [Green Version]

- Espitia, P.J.P.; de Fátima Ferreira Soares, N.; dos Reis Coimbra, J.S.; De Andrade, N.J.; Cruz, R.S.; Medeiros, E.A.A. Zinc Oxide Nanoparticles: Synthesis, Antimicrobial Activity and Food Packaging Applications. Food Bioprocess Technol. 2012, 5, 1447–1464. [Google Scholar] [CrossRef]

- Kliopova-Galickaja, I.; Kliaugaite, D. VOC emission reduction and energy efficiency in the flexible packaging printing processes: Analysis and implementation. Clean Technol. Environ. Policy 2018, 20, 1805–1818. [Google Scholar] [CrossRef]

- Stoler, J.; Weeks, J.R.; Fink, G. Sachet drinking water in Ghana’s Accra-Tema metropolitan area: Past, present, and future. J. Water Sanit. Hyg. Dev. 2012, 2, 223–240. [Google Scholar] [CrossRef] [PubMed]

| Sources | Search Criteria | String | First Search | Excluded | Analyzed |

|---|---|---|---|---|---|

| EBSCO Research date: 6 May 2020. | Time range: all years; article part: Pack * in title and Sustainab * and eco * in abstracts; documents: article; areas: all; the search criteria of containing the word “packaging” in the title was added to reduce the high number of articles (12,204). | Pack * AND Sustainab * AND Eco *. | 140 articles | 79 articles | 61 articles |

| Emerald Research date: 7 May 2020. | Time range: all years; article part: Pack * in abstract and Sustainab * and eco * in all the articles; documents: articles; areas: all; search. | Pack * AND Sustainab * AND Eco *. | 552 articles | 489 articles | 63 articles |

| Science Direct/Elsevier Research date: 5 May 2020. | Time range: all years (1978 to 2020); article part: all articles; documents: articles; areas: all; the criterion of containing the word “packaging” in the title was added to reduce the high number of articles (12,204 articles). | Packaging AND Sustainability AND eco (this base does not accept asterisk but considers similar words). | 204 articles | 27 articles | 177 articles |

| Springer Research date: 3 May 2020. | Time range: all years; article part: all; documents: articles and conference articles; areas: all; search string. | Pack * AND Sustainab * AND Eco *; containing pack * in the title. | 274 articles | 147 articles | 127 articles |

| Web of science Research date: 30 April 2020. | Time range: all years (1945 to 2020); article part: topic (title, abstract, author keywords and keywords); documents: articles and reviews; areas: all; main collections of Web Science. | Pack * AND Sustainab * AND Eco *. | 1374 articles | 970 articles | 404 articles |

| Willey Research date: 26 April 2020. | Time range: all years (1957 to 2020); article part: abstract; documents: article; areas: all. | Pack * AND Sustainab * AND Eco *. | 465 articles | 374 articles | 91 articles |

| Packaging Design Phases | Examples of Tools, Methods, Practices, and Data to Support Packaging Professionals Regarding Circular Economy and Sustainable Packaging |

|---|---|

| Briefing | Use of structural, graphical, and informational cues [90] |

| Analysis of sectoral agreements and regulations by packaging managers [47] | |

| Design of the supply chain network [113] | |

| Planning | Definition of raw material for packaging such as non-biodegradable plastics; biocomposites from vegetable oil-based biopolymers |

| Use of nanotechnology to extend product shelf life, improve biodegradability, or due to other demands (ex., food packaging, health packaging, etc.) | |

| Use of new technologies for packaging sustainability (active systems, intelligence) | |

| Use of system dynamics to plan packaging’s end of life [107] | |

| Analysis of sectoral agreements and regulations by the packaging team [47] | |

| Use of algorithm for reverse logistics optimization [34] | |

| Use of LCA to analyze the impact of production during the project stage [134] | |

| Identify raw material suppliers committed to packaging sustainability [127] | |

| Design | Strategy for private labels [38] |

| Visualization tool, which focuses on different parts of the participant’s view and experience of the development process in the project [5] | |

| Project of eco-labels using eye-tracking glasses [63] | |

| Requirements for a better packaging design/redesign Technical improvements; attention to external demands, management practices [61] | |

| Use of life cycle assessment for comparison of the performance of packaging materials [135] | |

| Implementation | Use of cost analysis techniques to implement packaging productive systems [91] |

| Use of best-worst scaling experiment in packaging project [10] | |

| Validation | Consumer’s perception of eco-friendly packaging: in terms of packaging materials, manufacturing technology; marketing appeal [91] |

| Routine of tests of innovative packaging systems [106] |

| Triangulation DP—CAT and LCS | Insights | Guideline Description |

|---|---|---|

| Briefing—circular economy (CE) and post-use | Briefing is more than the scope or requirements demanded by stakeholders for the packaging | Understand all stages of the packaging life cycle and the critical intersection points with the product life cycle |

| Briefing—sustainable practices and post-use | Briefing is the right moment to consider eliminating packaging | Analyze the packaging life cycle and promote the reduction or non-use of packaging within the supply chain. Understand the packaging needs of each product |

| Planning—dimension of sustainability and post-use | Sustainable education for packaging is as dependent on public policies as they are dependent on clear actions from the packaging planning phase | Identify global policies for the use and disposal of packaging materials and consumer education from the packaging planning phase |

| Planning—life cycle assessment and post-use | What is not measured over the entire packaging system cannot be improved | Observe, collect, and analyze demands from all stakeholders throughout the life cycle. Good integration between packaging and its contents, i.e., start with planning and must filling process and logistical specifications |

| Planning— material, extraction of raw material, and transformation | It is increasingly necessary to include in the packaging planning phase the search for recent materials and technologies to replace polymers | Consider the use of biocomposite materials from renewable resources to replace synthetic and non-biodegradable plastics |

| Planning—reverse logistics and filling process. | The type of waste and impact potentially generated by a package that already exists on the market is an important reference to start planning a new package | Start the planning at the packaging’s end of life to avoid a similar impact. Promote reverse logistics for new packaging and use techniques such as life cycle assessment (LCA) to compare the scenario with new and old packaging |

| Design—design stage and graphic and structural design | Graphic and structural design are more than creative actions. They must integrate the information gathered in the briefing and planning phases | Optimize existing designs or create lean packaging Reduce the use of materials (paints and special finishes), take advantage of useful areas, and reduce the number of scraps |

| Implementation— supply chain and packaging manufacturing | Implementation is more than manufacturing the packaging. It must integrate information gathered in the previous phases to avoid negative impact in the subsequent phase | Optimize packaging use along the supply chain. Understand impacts on packaging logistics and other aspects of the supply chain system |

| Validation—marketing, sale, and use | The packaging communication space can be better exploited to convey information about disposal, type of material used, and consumer awareness | Prioritize prime spaces on labels and packaging to include sustainable information. Highlight information about the materials used in the packaging, and their correct disposal |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sastre, R.M.; de Paula, I.C.; Echeveste, M.E.S. A Systematic Literature Review on Packaging Sustainability: Contents, Opportunities, and Guidelines. Sustainability 2022, 14, 6727. https://doi.org/10.3390/su14116727

Sastre RM, de Paula IC, Echeveste MES. A Systematic Literature Review on Packaging Sustainability: Contents, Opportunities, and Guidelines. Sustainability. 2022; 14(11):6727. https://doi.org/10.3390/su14116727

Chicago/Turabian StyleSastre, Ricardo Marques, Istefani Carísio de Paula, and Marcia Elisa Soares Echeveste. 2022. "A Systematic Literature Review on Packaging Sustainability: Contents, Opportunities, and Guidelines" Sustainability 14, no. 11: 6727. https://doi.org/10.3390/su14116727